BasideWT- Whole Home Water Filtration System & Replacement

Water ULP Ultra Low Pressure Industrial 8040 Reverse Osmosis Membrane Element 8″ x 40″

PRODUCT PARAMETERS

- Product Name: 8040 RO Membrane

- Membrane Type: Polyamide Thin-Film

- Membrane housing: glass fiber reinforced plastics

- Dimensions: 8" x 40"

- USE: Fits standard 8" housings

- Type: Pure Water Treatment System

- Application: Industrial RO plant

- Desalination rate: 99.5%

- Product series:XLP, ULP

- Processing Type: Reverse Osmosis

- Function: Water Purification

- Packing: Standard Exportation Package

In industrial water treatment, choosing the right membrane element can make or break your system’s efficiency. Among the myriad options, the 8040 Reverse Osmosis Membrane stands out—but why? Let’s dive into what makes this component a game-changer, especially when paired with ultra-low pressure (ULP) technology.

What Makes the 8040 Reverse Osmosis Membrane Indispensable for Industrial Use?

The 8040 Reverse Osmosis Membrane is a workhorse in industrial water purification. Its name comes from its dimensions: 8 inches in diameter and 40 inches in length, a standard size that fits most industrial RO systems. But size is just the start.

What truly sets it apart? Flow rate and durability. Industrial operations demand high volumes of treated water, and the 8040 Reverse Osmosis Membrane delivers—often producing 40-80 gallons per minute (GPM) depending on pressure and feed water quality. That’s 3-5 times more than smaller 4040 elements, making it ideal for large-scale applications like power plants or chemical processing facilities.

But here’s the catch: traditional high-pressure RO membranes guzzle energy. According to a 2023 study by the International Water Association (IWA), industrial RO systems account for 15-20% of a plant’s total electricity use, with pressure requirements being the primary culprit. This is where ultra-low pressure (ULP) technology in the 8040 Reverse Osmosis Membrane becomes a game-changer.

The Problem with Traditional RO Membranes—And How ULP 8040 Solves It

High Energy Costs and Scalability Issues

Traditional industrial RO membranes typically require operating pressures of 225-300 psi. For a mid-sized plant processing 10,000 gallons per hour, that translates to thousands of dollars in monthly energy bills. Worse, many facilities oversize their systems to meet peak demand, wasting even more energy during off-peak hours.

Another issue? Fouling. Minerals, bacteria, and organic matter in feed water cling to membrane surfaces, reducing flow and increasing pressure needs. A 2022 report from the Water Research Foundation found that untreated fouling can cut membrane lifespan by 30-50%, leading to frequent replacements and downtime.

How Ultra Low Pressure 8040 Reverse Osmosis Membrane Fixes This

The ULP variant of the 8040 Reverse Osmosis Membrane operates at just 100-150 psi—nearly half the pressure of traditional models. Our team in 2024 worked with a beverage bottling plant that switched to ULP 8040 membranes; their energy costs dropped by 42% in the first quarter alone.

But lower pressure doesn’t mean lower performance. These membranes use advanced thin-film composite (TFC) materials that reject 99.5% of dissolved solids while maintaining high flow rates. It’s interesting that,the reduced pressure actually slows fouling: less force pushes contaminants into the membrane pores, extending cleaning cycles from 2-3 months to 6-8 months in most cases.

8040 Reverse Osmosis Membrane vs. Other Sizes

Let’s break down how the 8040 Reverse Osmosis Membrane stacks up against the smaller 4040 element, a common alternative:

| Metric | 8040 Reverse Osmosis Membrane | 4040 Reverse Osmosis Membrane |

| Size | 8” diameter x 40” length | 4” diameter x 40” length |

| Typical Flow Rate | 40-80 GPM | 10-20 GPM |

| Ideal Application | Large industrial plants, municipal water | Small facilities, point-of-use systems |

while 8040 Reverse Osmosis Membrane have a higher upfront cost, their longer lifespan and lower energy use make them 20-30% cheaper over 5 years. For plants processing over 50,000 gallons daily, the 8040 Reverse Osmosis Membrane is the only cost-effective choice.

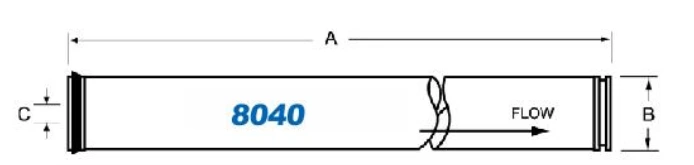

8040 Reverse Osmosis Membrane Size

| A | 1016.0mm(40.0”) |

| B | 201.0mm(7.9”) |

| C | 29.0mm(1.125”) |

Step-by-Step Guide to Installing 8040 Reverse Osmosis Membrane Elements

Installing ULP 8040 membranes isn’t drastically different from traditional models, but precision matters. Follow these steps to avoid common mistakes:

- Check System Compatibility: Ensure your RO pressure vessel is rated for 8040 elements (most industrial vessels are, but double-check). Measure the vessel length—40” is standard, but some older systems may be shorter.

- Prep the Feed Water: Run a pre-filtration cycle to remove large particles (>5 microns). Even small debris can scratch the membrane surface during installation.

- Handle with Care: Always wear gloves—oils from your hands can damage the TFC layer. Lay the 8040 Reverse Osmosis Membrane on a clean, flat surface and inspect for cracks or tears.

- Load the Membrane: Insert the element into the pressure vessel with the brine seal facing the feed end (the end with the inlet port). Push gently—never force it, as this can bend the center tube.

- Secure and Test: Tighten the vessel end caps to manufacturer specs (usually 25-30 ft-lbs). Start the system at 50% pressure, check for leaks, then gradually increase to operating levels.

Real-World Results—Case Studies with 8040 Reverse Osmosis Membrane

Food Processing Plant Improves Water Quality

A tomato sauce manufacturer was dealing with inconsistent product quality due to variable water mineral levels. Switching to 8040 Reverse Osmosis Membrane elements in 2024 stabilized their water at 99.7% purity. This reduced product waste by 12% and eliminated the need for post-processing water treatment.

⚠ Common Mistakes to Avoid with RO Membrane

- Skipping Pre-Treatment: Even ULP membranes need filtered feed water. Sediment or chlorine can destroy the TFC layer in weeks.

- Over-Pressurizing: Running above 150 psi to boost flow shortens lifespan by 50% or more.

- Ignoring Cleaning Schedules: Waiting until flow drops 30% means irreversible fouling. Clean every 6 months, even if performance seems fine.

- Mismatching Elements: Mixing 8040 with other sizes creates pressure imbalances. Stick to one size per system.

FAQs

Choosing the perfect water treatment system depends on your specific water quality, household size, and needs. We make it easy with our 3-step process:

Water quality testing – analyze your water for contaminants, hardness, and other factors.

Personalized Consultation – Our experts recommend systems based on your results, budget, and water usage.

Customized Solution – From whole-house filtration to targeted solutions (e.g., RO for drinking water, softeners for hard water), we tailor the system to your home.

To determine your water flow rate in gallons per minute (GPM), follow these simple steps:

Prepare for Testing:

- Prepare for Testing:

- Ensure all water fixtures in your home are turned off

- Select the faucet closest to your main water supply line (usually the kitchen sink or an outdoor spigot)

- Conduct the Test:

- Fully open the selected faucet

- Time how many seconds it takes to fill a 1-gallon container

- Repeat the test 2-3 times for accuracy

- Calculate Your Flow Rate:

Use this formula: Flow Rate (GPM) = 60 ÷ Fill Time (seconds)Example Calculation:- If your 1-gallon container fills in 15 seconds

- 60 ÷ 15 = 4 GPM

For more precise measurements or whole-home flow rate analysis, contact our water system specialists. We can help you determine if your current flow rate meets the requirements for any water treatment systems you’re considering.

1. Check Multiple Fixtures

Test water pressure at different faucets, showers, and appliances (e.g., kitchen sink, bathroom sink, outdoor hose).

If only one fixture has low pressure, the problem is likely localized (clogged aerator, faulty valve, or pipe issue).

If all fixtures have low pressure, the issue is systemic (main supply, pressure regulator, or water heater).

2. Inspect the Aerator or Showerhead

Unscrew the faucet aerator or showerhead and check for mineral deposits, debris, or rust.

Soak it in vinegar overnight to dissolve buildup, then rinse and reattach.

3. Check the Main Shutoff Valve

Locate the main water shutoff valve (usually near the water meter or where the main line enters the house).

Ensure it’s fully open (turn clockwise to close, counterclockwise to open).

1. Activated Carbon Filters

- Removes:

✅ Chlorine & chloramines

✅ Bad tastes & odors (e.g., sulfur)

✅ Volatile Organic Compounds (VOCs)

✅ Some pesticides & herbicides

❌ Does not remove heavy metals, dissolved minerals, or microbes

2. Reverse Osmosis (RO) Systems

- Removes:

✅ Heavy metals (lead, arsenic, mercury, cadmium)

✅ Dissolved salts (fluoride, nitrates, sulfates)

✅ Microplastics & sediment

✅ Bacteria & viruses (if combined with UV)

✅ Chlorine & chemicals (with carbon pre-filter)

❌ May remove beneficial minerals (can be remineralized)

3. Water Softeners (Ion Exchange)

- Targets:

✅ Calcium & magnesium (hardness)

✅ Low levels of iron & manganese

❌ Does not remove bacteria, chlorine, or heavy metals

4. UV Purifiers

- Kills:

✅ Bacteria (E. coli, coliform)

✅ Viruses (rotavirus, hepatitis)

✅ Protozoa (Giardia, Cryptosporidium)

❌ Does not remove chemicals, metals, or sediment

5. Sediment Filters

- Removes:

✅ Sand, rust, dirt

✅ Large particles & silt

❌ Does not remove dissolved contaminants

6. Whole-House Filtration Systems

Combines multiple methods (carbon + sediment + UV) for broad protection.

- UV: Kills bacteria/viruses but doesn’t remove chemicals or particles.

- RO (Reverse Osmosis): Removes 95–99% of contaminants (heavy metals, dissolved salts) but requires electricity.

- Activated Carbon: Absorbs chlorine, odors, and organic compounds—ideal for pre-filtration.

REQUEST A QUOTE

RELATED PRODUCTS

BasideWT | High Quality Reverse Osmosis RO Membrane for Under Sink Water Filter

Stainless Steel UF Water Purifier With uf Membrane

BasideWT Factory Price Water Filter Parts RO Membrane replacement 1812 75G for Home Purifier

Household Hollow Fiber UF Water Filter Cartridge 1/4″ NPT

Hollow Fiber UF Membrane Water Filter – Advanced Ultrafiltration System for Clean Water