BasideWT- Whole Home Water Filtration System & Replacement

FRP Tanks for Water Treatment | Custom FRP Tank Size & Design

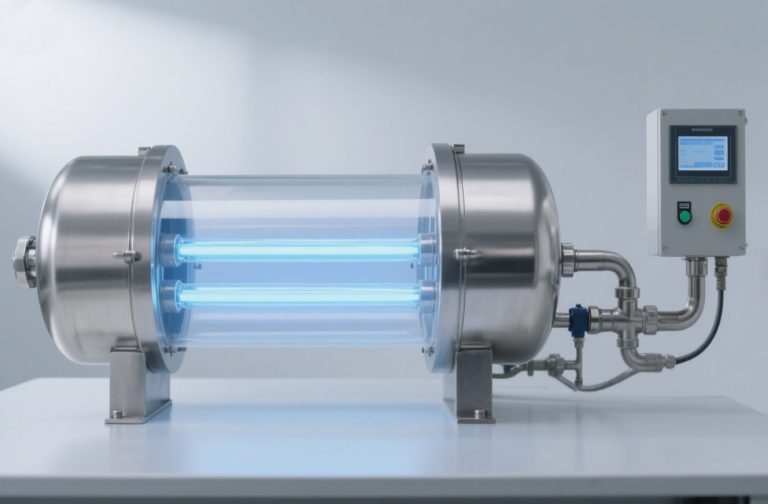

Selecting the correct storage solution is critical for any water treatment system’s efficiency and longevity. For engineers and project managers, this often comes down to a key decision: finding reliable FRP vessels for water treatment that perfectly align with their project’s specific frp tank size and pressure requirements. Standard, off-the-shelf tanks rarely fit complex industrial applications. This is where BasideWT’s expertise in custom-engineered FRP (Fiberglass Reinforced Plastic) tanks delivers unmatched value. We don’t just sell tanks; we provide precision-engineered containment solutions designed from the ground up to meet your exact process specifications, ensuring optimal performance, durability, and return on investment.

Why FRP? The Superior Material for Harsh Environments

Why has FRP become the material of choice for modern water treatment plants? The answer lies in its composite superiority. Unlike steel, which corrodes, or concrete, which can crack and leach, FRP offers an inert and highly resilient alternative.

- Excellent corrosion resistance: FRP tanks are impervious to the chemicals used in pretreatment, reverse osmosis, and wastewater neutralization, ensuring water purity and tank integrity.

- High strength and lightweight: They provide a high strength-to-weight ratio, making them easier to install than concrete and less costly to support than steel.

- Low maintenance and long lifespan: The non-reactive surface prevents scaling and biofilm adhesion, reducing maintenance needs and delivering a significantly longer service life.

Interestingly, while the upfront cost may be comparable to coated steel, the total cost of ownership for a custom FRP vessel for water treatment is often lower due to minimal upkeep and no requirement for periodic relining.

Common FRP Tank Size for Water Treatment

Standard FRP tanks commonly used in filtration, softening, and industrial water treatment systems

| Model No | Dia.X Height(mm) | Inch Size | Top Open | Bottom Open |

| 817 | Ø200×439 | 817 inch | 2.5 inch | N/A |

| 835 | Ø200×898 | 835 inch | 2.5 inch | N/A |

| 844 | Ø200×1130 | 844 inch | 2.5 inch | N/A |

| 935 | Ø225×900 | 935 inch | 2.5 inch | N/A |

| 1054 | Ø250×1391 | 1054 inch | 2.5 inch | N/A |

| 1252 | Ø300×1333 | 1252 inch | 2.5 inch | N/A |

| 1265 | Ø300×1663 | 1265 inch | 2.5 inch | N/A |

| 1354 | Ø325×1376 | 1354 inch | 2.5 inch | N/A |

| 1465 | Ø350×1655 | 1465 inch | 2.5 inch | N/A |

| 1665 | Ø400×1648 | 1665 inch | 2.5 inch | N/A |

| 1865 | Ø450×1805 | 1865 inch | 4 inch | N/A |

| 2069 | Ø500×1770 | 2069 inch | 4 inch | N/A |

| N/A | 4 inch | |||

| 2472 | Ø600×1920 | 2472 inch | 4 inch | N/A |

| N/A | 4 inch | |||

| 3072 | Ø750×1930 | 3072 inch | 4 inch | N/A |

| N/A | 4 inch | |||

| 3672 | Ø900×2120 | 3672 inch | 4 inch | 4 inch |

| 4072 | Ø1000×2170 | 4072 inch | 4 inch | 4 inch |

| 4872 | Ø1200×2130 | 4872 inch | 6 inch | 6 inch |

| 6072 | Ø1500×2250 | 6072 inch | 6 inch | 6 inch |

| 6386 | Ø1600×2420 | 6386 inch | 6 inch | 6 inch |

The BasideWT Advantage: Beyond Standard FRP Tank Sizing

At BasideWT, we understand that “custom” means more than adjusting dimensions. Our engineering process considers every variable that impacts performance.

- Precision Sizing & Geometry: We calculate the optimal frp tank size and shape—whether vertical, horizontal, cylindrical, or rectangular—based on your flow rate, residence time, and footprint constraints.

- Material Science: We tailor the resin matrix and glass fiber reinforcement to resist your specific chemical cocktail, whether it’s chlorine, sulfuric acid, or saline brine.

- Structural & Feature Integration: Tanks are designed for specific pressure ratings (vacuum to high-pressure) and include custom-fitted nozzles, manways, baffles, and internal coatings as needed.

Our Collaborative Design & Specification Process

How do we translate your needs into a perfect tank? Through a transparent, four-stage partnership.

- Stage 1: Consultation. We analyze your process flow diagram (PFD) and piping & instrumentation diagram (P&ID).

- Stage 2: Engineering Design. Our team creates detailed CAD models and stress reports for your approval.

- Stage 3: Fabrication. We utilize controlled filament winding and hand lay-up processes in our ISO-certified facility.

- Stage 4: Quality Assurance & Delivery. Every FRP tank for water treatment undergoes rigorous inspection and testing before shipment.

Technical Specifications and Common Applications

BasideWT FRP vessels are built to perform across the water cycle. Our standard range covers capacities from 1,000 to 50,000 gallons, but we regularly engineer larger custom solutions.

- Pretreatment: Raw water storage, coagulation/clarification tanks, and filter vessels.

- Core Treatment: RO/DI product and reject water storage, degasifiers, and ion exchange vessels.

- Post-Treatment & Reuse: Treated water holding, chemical dosing tanks, and wastewater equalization basins.

Specifically, for reverse osmosis systems, a properly sized FRP tank acts as a critical buffer, stabilizing system pressure and preventing frequent pump cycling. Conversely, an undersized tank can lead to operational inefficiency and increased wear.