BasideWT- Whole Home Water Filtration System & Replacement

DI Water for Car Washing: The Ultimate Guide to Perfect, Spot-Free Drying

DI Water for Car Washing

Imagine finishing a car wash and simply walking away as your vehicle air-dries to a perfect, streak-free shine. This isn’t magic—it’s science. For decades, mineral spots have been the inevitable nuisance of car washing. These stubborn white marks appear when tap water evaporates, leaving behind dissolved calcium, magnesium, and other impurities on your pristine paint.

However, a revolution is underway in the detailing world. Professional detailers and dedicated enthusiasts are discovering that DI water for car washing transforms this frustrating experience. By eliminating the root cause of water spots, this technology delivers consistently spectacular results. At BasideWT, we believe understanding the “why” behind the solution is just as important as the solution itself. This comprehensive guide will explore not just how deionized water systems work, but why they represent the final frontier in achieving automotive perfection.

The Unseen Enemy in Your Tap: Understanding Water Spots

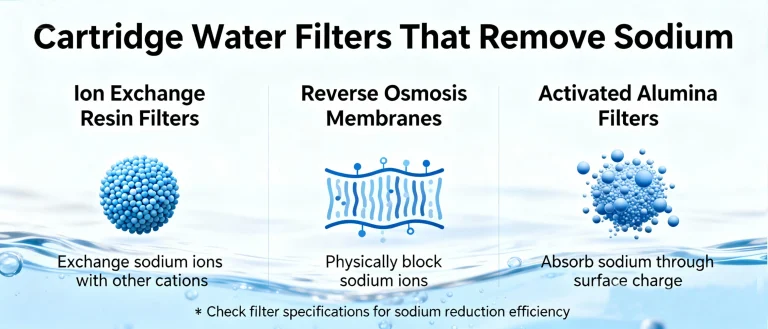

Before solving the problem, we must understand it. What we commonly call “water spots” are actually mineral deposits. Tap water, despite being clear and safe to drink, is far from pure. It contains a cocktail of dissolved Total Dissolved Solids (TDS)—primarily positively and negatively charged ions like calcium (Ca²⁺), magnesium (Mg²⁺), sodium (Na⁺), chloride (Cl⁻), and sulfate (SO₄²⁻).

The spotting process is a simple physical reaction:

- Contaminated water is sprayed onto your car’s surface.

- The pure H₂O molecules evaporate.

- The dissolved minerals have nowhere to go, so they crystallize onto your clear coat, glass, and trim.

These crystals are the hazy, chalky spots that can etch into your paint if left untreated, especially under direct sunlight which accelerates the evaporation process. Therefore, the only way to prevent them permanently is to remove the minerals before the water ever touches your car.

Demystifying the TDS Meter: Your Essential Spot-Free Guardian

A TDS meter is the most critical tool for anyone serious about DI water for car washing. But what does it actually measure?

Contrary to popular belief, a TDS meter does not count microscopic dirt particles. Instead, it measures the electrical conductivity of water. Dissolved ions are electrically charged, allowing them to carry a small current. The more ions present, the higher the conductivity, and the higher the TDS reading (in parts per million, or ppm).

However, it’s crucial to understand its limitation: a TDS meter is “ion-blind.” It cannot distinguish between hard, scale-forming calcium and softer sodium. This is vital because water with a TDS of 150 ppm comprised mostly of calcium will exhaust your DI resin much faster than water with the same TDS made of sodium.

So, how should you use it? Think of your TDS meter as a trend monitor, not a diagnostic lab. Its primary job is to tell you when your DI system’s output quality is declining, signaling that maintenance is needed. For DI water for car washing, you should always measure the water after it has passed through the system.

What TDS Level is Truly Spot-Free?

This is the most common question we hear at BasideWT. The answer depends on your standards and environment:

- 0-5 ppm (Ideal): Guarantees a spot-free finish even in direct, hot sunlight.

- 5-15 ppm (Excellent): Perfect for most conditions, especially in the shade or on overcast days.

- 15-25 ppm (Good): A noticeable improvement over tap water, but a gentle blot-dry with a clean towel is recommended for perfection.

Interestingly, the relationship between TDS and spotting isn’t perfectly linear. The type of ions remaining can influence spotting behavior, but aiming for the lowest possible number is always your safest bet.

The Science of Purity: How Mixed-Bed Deionization Works

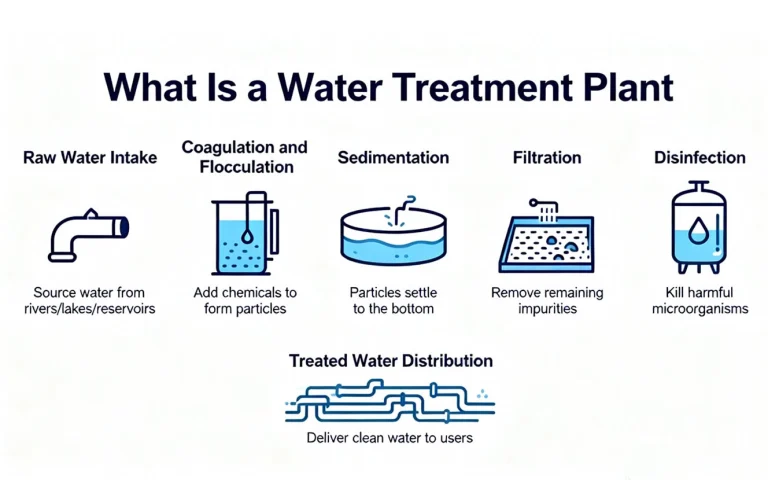

Now for the fascinating part: how a simple canister can transform spot-filled tap water into pure H₂O. A mixed-bed deionizer contains two specially engineered resins mixed together in a single chamber, creating a powerful purification process.

1. The Cation Exchange Resin (Fighting Positive Ions)

This resin starts in a “hydrogen form” (H⁺). As water flows through, it acts like a powerful magnet, grabbing onto positively charged ions (cations) like calcium, magnesium, and sodium. For every mineral ion it captures, it releases one harmless hydrogen ion (H⁺) into the water.

2. The Anion Exchange Resin (Fighting Negative Ions)

Simultaneously, the anion resin, which starts in a “hydroxide form” (OH⁻), captures all the negatively charged ions (anions) like chloride and sulfate. For every one of these it captures, it releases one hydroxide ion (OH⁻).

The Final, Elegant Reaction

Here’s where the magic happens. The hydrogen ions (H⁺) and hydroxide ions (OH⁻) released by the resins are instantly attracted to each other. They combine to form brand new, perfectly pure water molecules (H₂O).

Therefore, the system doesn’t just “filter” minerals; it chemically replaces them with more pure water. The output is water that is so pure, when it evaporates, it leaves behind absolutely nothing.

Maximizing Your System: Pro Tips for Efficiency and Longevity

Investing in a DI system is smart. Using it wisely is smarter. Here are proven strategies to get the most out of your resin and guarantee perfect results every time.

The Pre-Treatment Advantage: Softeners and Sediment Filters

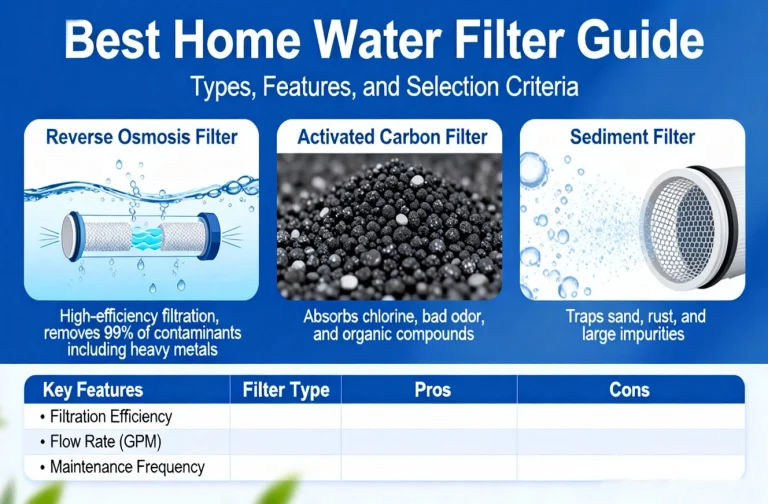

Counterintuitively, the best way to protect your DI system is to put something in front of it. If your tap water has very high TDS (over 200-300 ppm), sending it directly to the DI vessel will exhaust the resin quickly.

Specifically, we recommend:

- A Water Softener: This is the #1 pre-treatment for DI water for car washing. Softeners use a different process (ion exchange with sodium) to remove the hardness ions (calcium & magnesium) that are the most demanding on your DI resin. This dramatically extends its life.

- Sediment Filter: A simple 5-micron sediment filter will remove rust, sand, and dirt particles that could clog or foul the resin beads.

This two-stage approach is not only more cost-effective but also ensures consistently high-quality water.

The Final Rinse Method: Conserving Your Pure Water

Do you need to wash your entire car with DI water? Absolutely not. This is a common and costly mistake.

The most efficient method is:

- Initial Rinse & Wash: Use regular tap or softened water for the initial rinse, soap application, and wheel cleaning.

- The Final Rinse: This is the critical step. Switch your hose or pressure washer to the output of your BasideWT DI system. Use a gentle, low-pressure stream to flood the panels, allowing the pure water to sheet off contaminants.

This “final rinse only” method can make a single cartridge of resin last for dozens of washes, making the process both effective and economical.

Frequently Asked Questions (FAQ)

Q: What is the ideal TDS for a truly spot-free dry?

A: For guaranteed, perfect results, aim for 0-5 ppm. Many users find that results up to 10-15 ppm are acceptable, especially on overcast days or in the shade. As the TDS creeps higher, the risk of spotting increases, especially in direct sunlight.

Q: Can I connect my DI vessel directly to my pressure washer?

A: Only if your pressure washer’s flow rate (in GPM) is less than or equal to the flow rating of your DI system. Exceeding this flow rate means the water contacts the resin too briefly for proper deionization. The safest and most resin-efficient method is to use a dedicated DI rinse nozzle or a hose-end sprayer for the final rinse.

Q: My TDS is low, but I still see faint spots. Why?

A: There are two common culprits:

- Silica: Some DI systems are less effective at removing silica (SiO2), which can leave a faint, hazy residue.

- Contaminated Surfaces: If the car wasn’t washed properly and a layer of dirt or grime remains, the DI water can evaporate and leave this residue behind. The water itself is spot-free, but the surface wasn’t clean enough.

- Turbulent Rinsing: As mentioned above, a rough rinse creates clinging droplets that can leave a residue pattern.

Q: How do I know when to change my DI resin?

A: Your TDS meter is your guide. When the TDS of the water coming out of the DI system consistently exceeds your personal quality threshold (e.g., 10 ppm), it’s time to change the resin. You’ll often see the resin color change as it exhausts, but the TDS reading is the most reliable indicator.

SEND US AN EMAILFeel free to send us an email and we will reply to you as soon as possible.

CONTACT INFOWe are looking forward to hearing from you!

-

TEL: 86 13548779363

-

Email: sales@basidewt.com

-

Business hours: Monday to Friday (9AM – 10PM)

-

Address: Aibang Technology Industrial Park, No. 559 Yun Qi Lu,Yuelu District, Changsha, Hunan, China