BasideWT- Whole Home Water Filtration System & Replacement

How To Choose A Reverse Osmosis System

Overview

This definitive guide on how to choose a reverse osmosis (RO) system outlines the key steps for optimal selection. Reverse Osmosis is a pressure-driven membrane separation technology that efficiently removes dissolved solids and impurities, allowing only water molecules to pass through a semi-permeable membrane. It is critical for applications from seawater desalination to pharmaceutical production. An incorrect choice can result in low efficiency, high operational costs, or failure to meet water quality standards. Therefore, this guide provides engineers and decision-makers with a systematic methodology—integrating technical parameters, economic factors, and operational needs—to ensure the selection of a reliable and high-performance RO system.

How To Choose A Reverse Osmosis System

Water Demand

Determine the hourly, average, and peak water production requirements. System capacity should align with actual demand—smaller units may suffice for intermittent use, while continuous demand may require larger or multiple units operating in parallel.

Feed Water Quality

Feed water composition—hardness, total dissolved solids (TDS), suspended solids, organics, and microbial content—directly influences system design and membrane selection. For example, seawater with high salinity requires membranes with higher salt rejection rates.

Required Product Water Quality

Different applications have specific purity requirements. Electronics manufacturing, for instance, demands extremely low levels of particles, organics, microorganisms, and ions. Key parameters often include resistivity, Total Organic Carbon (TOC), bacterial counts, and particle size limits.

Application Context

RO systems are used in diverse settings: residential drinking water purification, industrial process water, seawater desalination, and laboratory water systems. Each context imposes different requirements for system size, automation, reliability, and output capacity.

Reverse Osmosis System Technical Parameters

(1) Operating Parameters

- Operating Pressure: Typically 0.5–1.6 MPa, depending on system design and application.

- Operating Temperature: Generally between 5–45°C; specific membrane materials may have different temperature tolerances.

- Power Supply: Common voltages include 220V and 380V, selected based on system power and local electrical standards.

(2) Membrane Specifications

- Membrane Type: Common materials include polyamide and polysulfone. Variations offer different separation performance, chemical resistance, and temperature stability.

- Membrane Area: Larger membrane area typically increases output but also system size and cost.

- Salt Rejection Rate: High-quality RO membranes should achieve ≥95% salt rejection for effective removal of dissolved solids.

(3) Water Quality Parameters

- Feed Water Quality: Hardness, TDS, turbidity, organics, microbial load, etc.

- Product Water Quality: Must meet target standards such as resistivity, TOC, bacterial limits, and particle counts.

Reverse Osmosis System Selection Recommendations

- Demand Analysis: Clarify water usage, required volume, target quality, and site conditions.

- Technical Evaluation: Based on water analysis reports, select appropriate pretreatment processes and RO membrane type.

- Economic Comparison: Consider full life-cycle cost (CAPEX + OPEX) and evaluate supplier quotations for value.

- Solution Validation: Request simulation data or pilot testing from suppliers to verify performance.

- Contract Confirmation: Ensure performance guarantees (e.g., salt rejection, output volume), warranty terms, and service details are clearly stated.

(1) Membrane Selection

The membrane is the core of the RO system. Choose based on feed water quality, treatment goals, and operating environment—e.g., high-salinity seawater requires membranes with superior rejection rates.

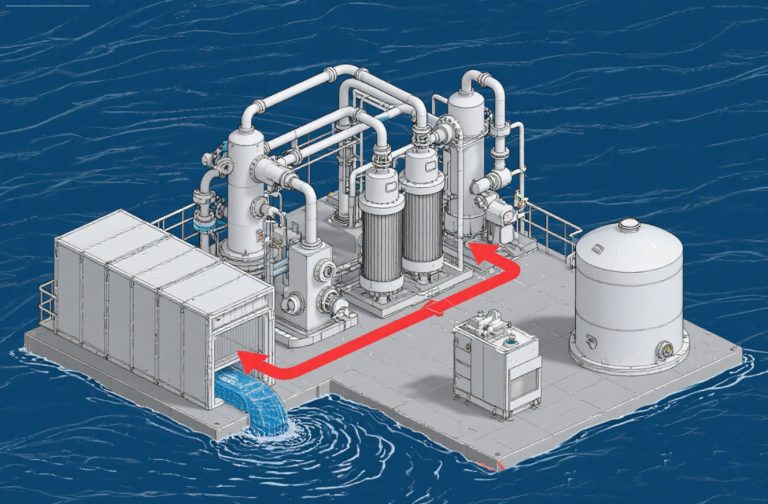

(2) System Design

A typical RO system includes pretreatment, RO unit, and post-treatment sections. Pretreatment (e.g., multimedia filtration, activated carbon, softeners) protects membranes from fouling. Each section must be properly sized and integrated for optimal performance.

(3) Pretreatment & Post-Treatment

Pretreatment may include sand filters, carbon filters, water softeners, and cartridge filters. Post-treatment (such as polishing filters or remineralization) adjusts water quality to meet final user specifications.

(4) Brand & Quality

Select equipment from reputable manufacturers with proven experience, advanced technology, and reliable after-sales support to ensure system durability and performance.

Applications & Case Examples

RO systems serve a wide range of sectors:

- Residential: Under-sink units providing safe drinking water.

- Industrial: High-purity water for food & beverage, pharmaceuticals, electronics, and manufacturing.

- Seawater Desalination: Converting seawater to potable water in water-scarce regions.

- Laboratories: Supplying ultrapure water for precise experimental results.

Reverse Osmosis System Installation & Maintenance

(1) Installation Guidelines

- Install on a solid, level foundation to avoid vibration and instability.

- Connect inlet/outlet piping and electrical supply securely, ensuring leak-free seals.

- Follow correct sequence and configuration for pretreatment and post-treatment units to ensure smooth flow.

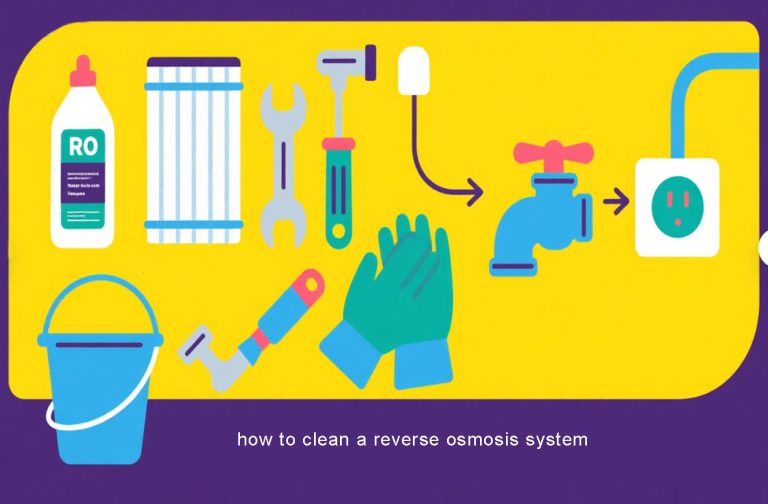

(2) Maintenance Guidelines

- Monitor operating parameters (pressure, flow, water quality) regularly to detect anomalies.

- Replace filter cartridges, membranes, and other consumables as recommended.

- Perform periodic cleaning and sanitization to prevent biofouling and membrane scaling.

- Conduct routine upkeep: wipe down surfaces, inspect tubing, and keep the system clean.

Important Considerations

- Temperature Control: Operate at ≤50°C; keep away from heat sources.

- Freeze Protection: Drain pipelines during winter shutdowns to prevent ice damage.

- After-Sales Service: Choose suppliers offering 24/7 technical support for rapid troubleshooting.

Future Trends

- Smart RO Systems: AI-driven fouling prediction and IoT-based remote monitoring and maintenance.

- Advanced Materials: Graphene-based membranes and forward osmosis (FO) hybrid systems for improved energy efficiency.

- Zero Liquid Discharge (ZLD): Integrated RO with evaporation/crystallization technologies to minimize wastewater discharge.