BasideWT- Whole Home Water Filtration System & Replacement

What is an FRP Tank?

What is an FRP tank? It’s a storage solution made from Fiberglass Reinforced Plastic. This material is incredibly strong and durable. Therefore, it is the top choice for many tough industrial jobs. This guide dives deep into everything you need to know. We will explore its makeup, benefits, and top applications. Specifically, we will highlight its critical role in advanced water purification systems like the BasideWT DI Water System.

Understanding FRP Tank Composition and Manufacturing

So, what exactly goes into an FRP tank? The name gives the first clue. Fiberglass Reinforced Plastic combines two main parts. Let’s break down this powerful duo.

The Core Components: Fiberglass and Resin

The “reinforcement” is the fiberglass. Think of strong, interwoven glass fibers. These fibers provide the structural strength. They are the skeleton of the tank. However, a skeleton alone isn’t enough. It needs a binding material.

That’s where the “plastic” or resin comes in. The resin is a polymer matrix, often polyester or vinyl ester. It coats the fiberglass strands. This coating binds them together into a solid structure. Therefore, the resin gives the tank its shape and corrosion resistance. The combination is phenomenal. You get the strength of glass and the resilience of advanced plastics.

The Construction Process: How FRP Tanks Are Built

Building an FRP tank is a precise art. Two main methods are used: filament winding and hand lay-up. Filament winding is highly automated. Continuous fiberglass strands are soaked in resin. Then, they are wound around a rotating mold. This creates consistent, high-strength walls. Conversely, the hand lay-up method involves workers manually applying layers of fiberglass matting and resin. This process is more labor-intensive. However, it allows for greater customization of complex shapes. Both methods produce a seamless, monolithic structure. This structure is free from weak points like welds.

Key Advantages of Using FRP Storage Tanks

Why choose an FRP tank over other materials like steel or polyethylene? The benefits are numerous and significant. They make FRP a superior choice in countless scenarios.

Superior Corrosion Resistance for Harsh Chemicals

This is the biggest advantage. FRP tanks laugh in the face of corrosion. They resist a vast range of chemicals. Acids, alkalis, and solvents are no match for them. Steel tanks, in contrast, rust and degrade quickly. Therefore, FRP tanks last much longer in aggressive environments. This leads to huge cost savings. You avoid frequent replacements and costly repairs.

Exceptional Strength-to-Weight Ratio

FRP tanks are incredibly strong yet surprisingly light. Imagine a tank as sturdy as steel but weighing only a fraction. This makes them easier to transport and install. Logistics become simpler. Installation costs drop. You don’t need heavy cranes or extensive groundwork. Despite their light weight, they handle high pressures with ease.

Long Service Life and Low Maintenance Needs

Durability is a hallmark of FRP. A well-made FRP tank can last for decades. It does not rust, rot, or corrode. Unlike steel, it never needs painting or cathodic protection. Maintenance is minimal. Essentially, you install it and forget it. This reliability provides peace of mind and a fantastic return on investment.

FRP Tank Applications Across Various Industries

Where do you find these versatile tanks? The answer is almost everywhere. Their unique properties make them indispensable across multiple sectors.

Water and Wastewater Treatment Systems

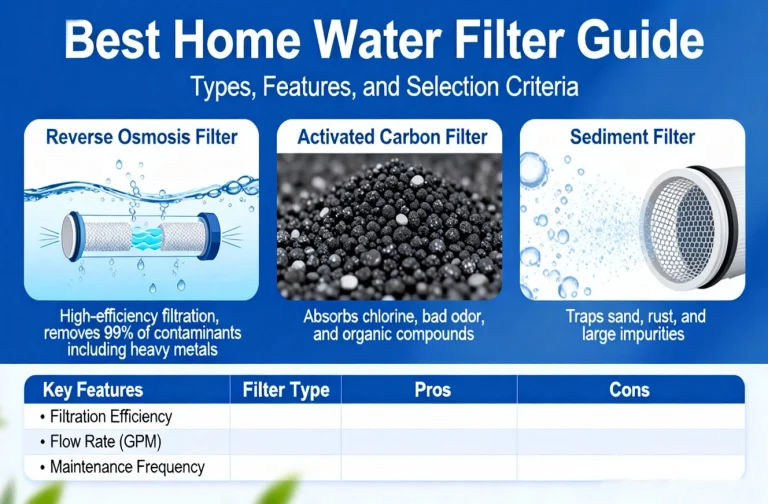

This is a primary application. FRP tanks are perfect for storing and treating water. They hold chemicals like chlorine and ferric chloride. Furthermore, they serve as vessels for filtration processes. For instance, they are ideal for pressure sand filters, activated carbon filters, and, most importantly, ion exchange systems. This is where the BasideWT DI Water System excels. Its FRP construction ensures pure water output without contamination.

Chemical Processing and Industrial Plants

Chemical plants rely heavily on FRP storage. They safely store raw materials and finished products. From hydrochloric acid to sodium hydroxide, FRP tanks handle it all. They are also used as process vessels, scrubbers, and distillation columns. Their corrosion resistance is absolutely critical for plant safety and efficiency.

Pulp and Paper Manufacturing and Other Sectors

The pulp and paper industry uses aggressive chemicals. These include chlorines and hypochlorites. FRP tanks are the standard for containing these liquids. Other key sectors include metal finishing, pharmaceuticals, and power generation. In every case, FRP provides a safe, reliable, and cost-effective storage solution.

The Critical Role of FRP in Deionized Water Systems

Deionized (DI) water is ultra-pure. It is essential for laboratories, pharmaceuticals, and electronics manufacturing. However, producing DI water requires a special vessel. Why is FRP the perfect material for this job?

Why FRP is Ideal for DI Water Production

The ion exchange process inside a DI system is sensitive. It requires a perfectly clean environment. Any contamination will ruin the water’s purity. Metal tanks can leach ions (like iron) into the water. This defeats the entire purpose. Conversely, FRP tanks are inert. They do not react with the water or the ion exchange resin. Therefore, they guarantee the highest possible water quality. The BasideWT DI Water System leverages this inertness to deliver consistently high-purity water.

Protecting Water Purity and System Integrity

Purity is paramount. FRP tanks ensure no external contaminants enter the water stream. They also protect the system from internal damage. The regenerant chemicals used in DI systems, such as acid and caustic soda, are highly corrosive. An FRP tank withstands these chemicals effortlessly. This dual protection—safeguarding both the water and the equipment—makes FRP indispensable.

FRP vs. Alternative Tank Materials: A Detailed Comparison

Choosing a tank material is a big decision. How does FRP stack up against the competition? Let’s compare the most common options.

FRP Tanks vs. Steel Tanks: Corrosion is Key

Steel is strong and widely used. But it has a fatal flaw: rust. Even with coatings, steel is vulnerable to corrosion. This limits its lifespan, especially with chemicals. Maintenance is constant and expensive. FRP, however, is inherently corrosion-proof. It offers a longer life with far lower lifetime costs. For corrosive services, FRP is the clear winner.

FRP Tanks vs. Polyethylene Tanks: Strength Matters

Polyethylene (PE) tanks are cheap and good for mild applications. But they have major weaknesses. They are not as strong as FRP. They can become brittle in cold weather and soften in heat. UV radiation from the sun can also degrade them. FRP tanks offer superior structural strength, better temperature resistance, and customizability. For any demanding industrial application, FRP is the more robust and reliable choice.

Selecting and Maintaining Your FRP Storage Solution

You’re convinced an FRP tank is right for you. What’s next? Proper selection and care are vital for maximizing performance.

Key Selection Criteria for Your FRP Vessel

Consider these factors carefully. First, what chemical will you store? Confirm the resin type is compatible. Second, determine the required capacity and dimensions. Third, consider the operating temperature and pressure. Finally, look at certifications and standards. Reputable manufacturers provide clear guidance. For a system like the BasideWT DI Water System, this selection is done for you, ensuring optimal performance.

Essential Maintenance Tips for Longevity

While low-maintenance, FRP tanks aren’t zero-maintenance. Follow these simple tips. Perform regular visual inspections. Look for any signs of damage, like cracks or blisters. Keep the exterior clean. Ensure all connections and fittings are tight. Most importantly, never exceed the tank’s design limits for chemical concentration, temperature, or pressure. This simple care will ensure your tank serves you well for decades.