BasideWT- Whole Home Water Filtration System & Replacement

What is the Lifespan of an Offshore Water Treatment System?

When considering offshore operations, one of the most critical questions is: What is the lifespan of an offshore water treatment system? The lifespan of these systems is influenced by various factors, including environmental conditions, the type of technology used, and the level of maintenance and monitoring. Offshore water treatment systems play a crucial role in ensuring the safe and sustainable supply of clean water for oil rigs, ships, and remote maritime installations.

In this article, we will explore the lifespan of offshore water treatment systems in-depth, examining the different types of systems, how they are maintained, and what affects their longevity. Whether you are involved in offshore operations or simply curious about the technology, this guide will provide valuable insights.

The Role of Offshore Water Treatment Systems

Before diving into the specifics of their lifespan, it’s important to understand why these systems are critical. Offshore water treatment systems are designed to treat seawater, desalinate it, or purify it for use in various offshore operations, including oil and gas extraction, ship operations, and offshore platforms. These systems are necessary to ensure that clean water is available for drinking, sanitation, and even some industrial processes.

1. Desalination and Filtration

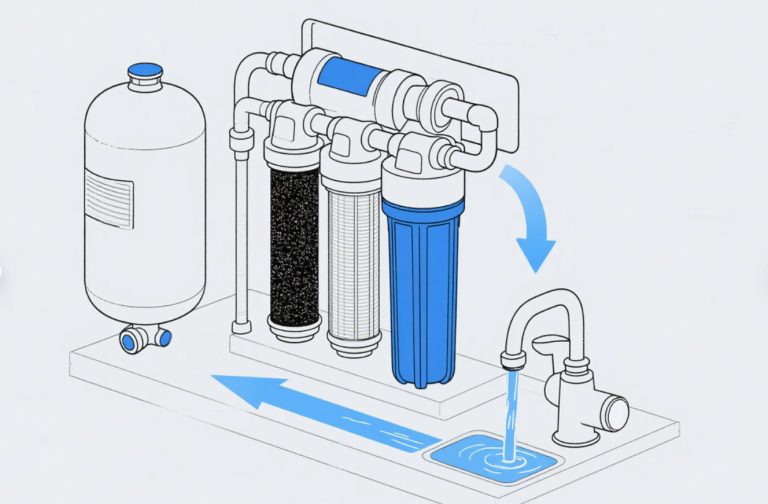

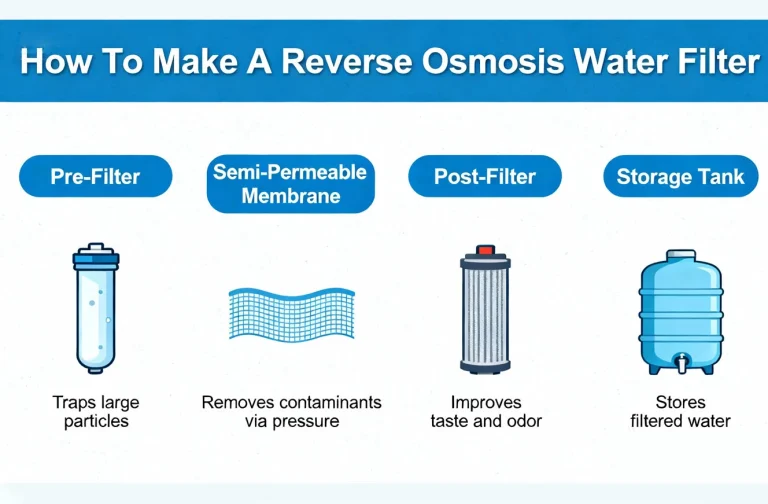

Offshore water treatment systems often incorporate desalination processes like reverse osmosis (RO) or distillation to remove salt and other impurities from seawater. This makes seawater suitable for human consumption or other industrial needs.

2. Maintaining Crew Health

For offshore workers, access to clean water is not just a convenience but a necessity for health and hygiene. These systems ensure that the crew has an adequate water supply, free from harmful contaminants.

3. Environmental Compliance

Offshore platforms and vessels must comply with environmental regulations regarding water discharge. Effective water treatment systems play a key role in maintaining compliance with international maritime laws and reducing ecological impact.

What Factors Affect the Lifespan of Offshore Water Treatment Systems?

When assessing the lifespan of an offshore water treatment system, multiple factors come into play. These include:

1. Environmental Conditions

Offshore water treatment systems are exposed to harsh marine environments. Saltwater, corrosive elements, and extreme weather conditions can accelerate wear and tear. Systems must be designed with durable materials and protective coatings to withstand the challenges of the offshore environment.

- Saltwater Corrosion: One of the most significant threats to the longevity of offshore water treatment systems is saltwater corrosion. The constant exposure to saline water can degrade materials over time, leading to system failures.

- Harsh Weather: Offshore systems are subjected to unpredictable and extreme weather conditions, from storms to temperature fluctuations, which can affect the performance and lifespan of the system.

2. Maintenance and Monitoring

Routine maintenance is essential to extend the lifespan of offshore water treatment systems. Neglecting this can result in reduced efficiency, costly repairs, or even system failure.

- Scheduled Inspections: Regular inspection of critical components, such as membranes in reverse osmosis systems, can detect wear before it becomes a major problem.

- Preventative Maintenance: Cleaning and servicing key components like filters and pumps help to prevent clogging or damage. Regular replacement of membranes, seals, and other consumables can extend the system’s overall life.

3. Technological Advancements

The specific type of water treatment technology used also influences the system’s lifespan. Some systems, like reverse osmosis, may require more frequent maintenance or replacement of components, while others may be more robust.

- Reverse Osmosis Systems: These systems often have a shorter lifespan due to the wear and tear on their membranes. Regular maintenance, including cleaning and membrane replacement, is critical.

- Distillation Systems: While generally more robust, distillation units still require periodic servicing to maintain efficiency.

Typical Lifespan of Offshore Water Treatment Systems

The lifespan of an offshore water treatment system varies depending on several factors, but on average, these systems last between 10 to 25 years. Here’s a breakdown of typical lifespans for different types of systems:

1. Reverse Osmosis (RO) Systems

- Average Lifespan: 10 to 15 years.

- Factors Influencing Longevity: The lifespan of reverse osmosis systems is primarily dependent on the membrane’s durability. Frequent cleaning and proper maintenance can extend the system’s useful life. However, the high cost of replacement membranes can become a limiting factor.

2. Desalination Plants (Multi-Stage Flash Distillation)

- Average Lifespan: 20 to 25 years.

- Factors Influencing Longevity: Desalination plants are often built with high-grade materials designed to withstand the harsh offshore conditions. Their lifespan is longer than that of RO systems, but they still require routine maintenance and periodic updates to keep the system running efficiently.

3. Electrodialysis Systems

- Average Lifespan: 15 to 20 years.

- Factors Influencing Longevity: Electrodialysis is often used in niche applications, but its longevity depends on the level of scaling and fouling in the system, which requires routine maintenance.

Maintenance Practices to Extend the Lifespan of Offshore Water Treatment Systems

As we’ve seen, maintaining an offshore water treatment system is critical to extending its lifespan. Let’s now dive deeper into the best practices for ensuring the longevity of these systems:

1. Regular Cleaning and Filtration Replacement

For systems like reverse osmosis, frequent cleaning and replacement of filters and membranes can significantly extend the system’s life. Accumulated minerals, salts, and biological contaminants can clog filters and membranes, reducing efficiency and lifespan.

- RO System Cleaning: Reverse osmosis membranes should be cleaned every 6 to 12 months, depending on water quality and system usage.

- Filter Replacement: Pre-filters and post-filters in RO systems should be replaced according to the manufacturer’s guidelines.

2. Routine Inspection and Monitoring

Routine inspections ensure early detection of any malfunctions or issues that may arise. Implementing a predictive maintenance program allows for the use of sensors and remote monitoring systems to detect problems in real time.

- Inspections: Checking for salt deposits, leaks, and corrosion at least twice a year.

- Monitoring: Using pressure sensors, flow meters, and water quality sensors to monitor system performance.

3. Use of Corrosion-Resistant Materials

Investing in corrosion-resistant materials for key system components can drastically reduce maintenance needs and extend the system’s life. Stainless steel, titanium, and specialized coatings can help prevent damage caused by exposure to saltwater.

Case Study: Offshore Water Treatment System on an Oil Platform

To better illustrate the importance of maintenance and the factors affecting lifespan, let’s look at a real-world example. An oil platform in the North Sea relied on a reverse osmosis system to treat seawater for both drinking water and industrial use.

Problem:

The system started experiencing reduced water production after 10 years of service. Maintenance crews noticed that the membranes were heavily fouled with scaling, and some pipes showed signs of corrosion.

Solution:

After conducting a thorough inspection, it was determined that the primary cause of the issues was a lack of regular cleaning and replacement of the membranes. The maintenance team replaced the membranes, conducted a full cleaning of the system, and upgraded the piping with corrosion-resistant materials.

Outcome:

The water treatment system was restored to full functionality, and the lifespan was extended by another 5 years. Regular monitoring and preventative maintenance were put in place to prevent similar issues in the future.