BasideWT- Whole Home Water Filtration System & Replacement

FRP Vessels for Water Treatment | Custom frp Pressure Vessel Manufacturers

PRODUCT PARAMETERS

- Product Name: FRP Vessels for Water Treatment

- Material: Epoxy Resin, Glass Fiber

- Color: Nature/Blue/Black/Grey/Green

- Filter media: quartz sand, activated carbon, soft water resin

- Processing Type: Reverse Osmosis, filtration, Softening

- Core Components: Pressure vessel

- Performance: High efficiency filter

- Working Pressure: 100 psi and 150 psi

- Operating Temperature: 1-49°C(34-120°F)

- Type: Water Filtration

- Packing: Standard Exportation Package

When building a reliable and efficient water treatment system, the choice of pressure vessel is critical. For engineers and project managers seeking a superior alternative to traditional metal tanks, FRP Vessels for Water Treatment | Custom FRP Pressure Vessel Manufacturers offer an unbeatable combination of durability, corrosion resistance, and design flexibility. But what makes these vessels so reliable? Simply put, their construction from Fiber Reinforced Plastic (FRP) creates a robust, inert barrier that withstands harsh chemicals and varying pressures without succumbing to rust or contamination. As a leading custom FRP pressure vessel manufacturer, BasideWT specializes in engineering solutions that meet the precise demands of modern water purification.

Why Choose FRP Over Traditional Materials?

Compared to steel or concrete, FRP presents a compelling case. Firstly, FRP is incredibly lightweight, slashing installation and transportation costs. Secondly, and most importantly, it is inherently corrosion-proof. This eliminates the need for costly linings or cathodic protection required for metal tanks. Therefore, systems for reverse osmosis, filtration, or softening last longer with minimal maintenance. Interestingly, while metals weaken with corrosion, FRP maintains its structural integrity over decades, even when constantly exposed to oxidants, chlorine, or fluctuating pH levels.

The BasideWT Custom Design & Engineering Process

At BasideWT, we understand that every water treatment project is unique. How do we ensure a perfect fit? Our process begins with a deep analysis of your operational parameters.

- Application-Specific Design: We consider flow rates, operating pressure (PSI), and the specific treatment media.

- Material Science Selection: We choose the optimal resin matrix and fiber orientation for your chemical environment.

- Precision Manufacturing: Using advanced filament winding and computer-controlled processes, we build each vessel for consistent, reliable performance.

However, it is worth noting that, a true custom design doesn’t just alter dimensions; it re-engineers the vessel from the laminate structure outwards to optimize for your exact service life and safety requirements.

FRP Vessels for Water Treatment

Custom FRP pressure vessels are versatile workhorses. They serve as the critical containment shell in several key processes:

- Reverse Osmosis (RO) Systems: Housing semi-permeable membranes under high pressure.

- Filtration Vessels: Containing sand, activated carbon, or multimedia filters for particle and contaminant removal.

- Water Softening: Holding ion-exchange resin to remove calcium and magnesium ions.

- De-aeration and Degasification: Where their corrosion resistance is vital.

Specifically, in a large-scale municipal softening plant, our vessels manage constant cyclic loading without fatigue, a common failure point in less resilient materials.

Technical Advantages & Long-Term Value

The investment in a high-quality FRP Vessels for Water Treatment pays dividends for years. Let’s examine the key advantages:

- Zero Corrosion, Zero Rust: Ensures effluent water purity is never compromised.

- High Strength-to-Weight Ratio: Enables easier installation and structural support.

- Smooth Internal Surface: Reduces friction loss and prevents biofilm adhesion.

- Low Thermal Conductivity: Improves process efficiency without heat loss.

Counterintuitively, although the upfront cost may be comparable to lined steel, the total lifetime cost of an FRP vessel is often significantly lower due to its negligible maintenance and replacement needs.

Why Choose BasideWT FRP Water Storage Tank

SEND US AN EMAIL

Our BasideWT water specialists are ready to assist.

FAQs

Choosing the perfect water treatment system depends on your specific water quality, household size, and needs. We make it easy with our 3-step process:

Water quality testing – analyze your water for contaminants, hardness, and other factors.

Personalized Consultation – Our experts recommend systems based on your results, budget, and water usage.

Customized Solution – From whole-house filtration to targeted solutions (e.g., RO for drinking water, softeners for hard water), we tailor the system to your home.

To determine your water flow rate in gallons per minute (GPM), follow these simple steps:

Prepare for Testing:

- Prepare for Testing:

- Ensure all water fixtures in your home are turned off

- Select the faucet closest to your main water supply line (usually the kitchen sink or an outdoor spigot)

- Conduct the Test:

- Fully open the selected faucet

- Time how many seconds it takes to fill a 1-gallon container

- Repeat the test 2-3 times for accuracy

- Calculate Your Flow Rate:

Use this formula: Flow Rate (GPM) = 60 ÷ Fill Time (seconds)Example Calculation:- If your 1-gallon container fills in 15 seconds

- 60 ÷ 15 = 4 GPM

For more precise measurements or whole-home flow rate analysis, contact our water system specialists. We can help you determine if your current flow rate meets the requirements for any water treatment systems you’re considering.

1. Check Multiple Fixtures

Test water pressure at different faucets, showers, and appliances (e.g., kitchen sink, bathroom sink, outdoor hose).

If only one fixture has low pressure, the problem is likely localized (clogged aerator, faulty valve, or pipe issue).

If all fixtures have low pressure, the issue is systemic (main supply, pressure regulator, or water heater).

2. Inspect the Aerator or Showerhead

Unscrew the faucet aerator or showerhead and check for mineral deposits, debris, or rust.

Soak it in vinegar overnight to dissolve buildup, then rinse and reattach.

3. Check the Main Shutoff Valve

Locate the main water shutoff valve (usually near the water meter or where the main line enters the house).

Ensure it’s fully open (turn clockwise to close, counterclockwise to open).

1. Activated Carbon Filters

- Removes:

✅ Chlorine & chloramines

✅ Bad tastes & odors (e.g., sulfur)

✅ Volatile Organic Compounds (VOCs)

✅ Some pesticides & herbicides

❌ Does not remove heavy metals, dissolved minerals, or microbes

2. Reverse Osmosis (RO) Systems

- Removes:

✅ Heavy metals (lead, arsenic, mercury, cadmium)

✅ Dissolved salts (fluoride, nitrates, sulfates)

✅ Microplastics & sediment

✅ Bacteria & viruses (if combined with UV)

✅ Chlorine & chemicals (with carbon pre-filter)

❌ May remove beneficial minerals (can be remineralized)

3. Water Softeners (Ion Exchange)

- Targets:

✅ Calcium & magnesium (hardness)

✅ Low levels of iron & manganese

❌ Does not remove bacteria, chlorine, or heavy metals

4. UV Purifiers

- Kills:

✅ Bacteria (E. coli, coliform)

✅ Viruses (rotavirus, hepatitis)

✅ Protozoa (Giardia, Cryptosporidium)

❌ Does not remove chemicals, metals, or sediment

5. Sediment Filters

- Removes:

✅ Sand, rust, dirt

✅ Large particles & silt

❌ Does not remove dissolved contaminants

6. Whole-House Filtration Systems

Combines multiple methods (carbon + sediment + UV) for broad protection.

- UV: Kills bacteria/viruses but doesn’t remove chemicals or particles.

- RO (Reverse Osmosis): Removes 95–99% of contaminants (heavy metals, dissolved salts) but requires electricity.

- Activated Carbon: Absorbs chlorine, odors, and organic compounds—ideal for pre-filtration.

REQUEST A QUOTE

RELATED PRODUCTS

Stainless Steel Water Tank Industrial Water Softener Tanks Rustproof Pressure Vessels for RO Systems | OEM Pricing

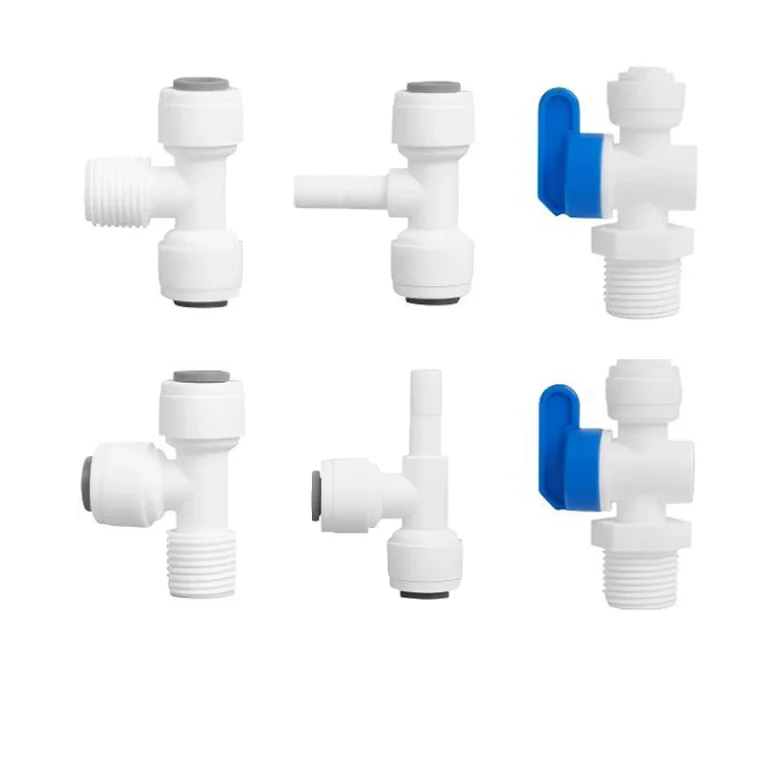

Quick Connect RO Water Filter Fittings Three-Way Fittings 4 Turn 2 Quick Ball Valve

Top and Bottom Water Treatment Water Distributor for FRP Tank

1354 frp Vessel Fiberglass Water Storage Tanks BasideWT

High Flow Cartridge Filter Housing | BasideWT Manufacturer