BasideWT- Whole Home Water Filtration System & Replacement

Extra Low Pressure ULP 4040 RO Membrane Element – 4 x 40 Inches for Low TDS Water

PRODUCT PARAMETERS

- Product Name: 4040 RO Membrane

- Membrane Type: Polyamide Thin-Film

- Dimensions: 4" x 40"

- USE: Fits standard 4" housings

- Type: Pure Water Treatment System

- Application: PIndustrial RO plant

- Desalination rate: 99.5%

- Product series: XLP, ULP

- Processing Type: Reverse Osmosis

- Function: Water Filtration

- Packing: Standard Exportation Package

Introduction: Why the 4040 RO Membrane Matters

Reverse osmosis technology is crucial for clean water production, and the 4040 membrane is a game-changer for industrial and commercial applications. But what makes it stand out?

Unlike standard membranes, the ULP membrane operates at extra-low pressure, reducing energy costs by up to 30% (Source: Water Technology Journal, 2023). Plus, its 4 x 40-inch design ensures higher flow rates with compact installation.

In this guide, we’ll explore its benefits, compare it with alternatives, and share real-world insights—like how our team optimized a beverage plant’s filtration system in 2025 using this membrane.

Key Advantages of the 4040 RO Membrane

Energy Efficiency & Cost Savings

The ULP 4040 membrane requires lower operating pressure compared to traditional membranes (100+ psi). This means:

- ⚡ Lower electricity bills🔧 Reduced pump wear🌍 Smaller carbon footprint

High Rejection Rates & Durability

Most 4040 RO membranes boast:

- ✔ 98%+ salt rejection (ensuring pure water)

- ✔ Longer lifespan (3-5 years with proper care)

- ✔ Fouling resistance (thanks to advanced polyamide layers)

⚠ Note: Avoid high chlorine exposure—it degrades membrane performance!

4040 RO Membrane vs. Competing Models

Here’s a quick comparison table to help you decide:

| Feature | ULP 4040 RO Membrane | Standard 8040 Membrane |

|---|---|---|

| Operating Pressure | 50-100 psi | 150-200 psi |

| Energy Consumption | Low (30% less) | High |

| Footprint | Compact (4″ diameter) | Bulky (8″ diameter) |

| Best For | Small-to-medium systems | Large-scale plants |

Interesting fact: The 4040 size is ideal for modular setups, allowing easy scalability.

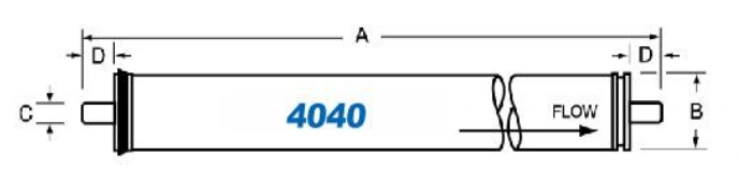

4040 RO Membrane Size

| A | 1016.0mm(40.0”) |

| B | 99.7mm(3.9”) |

| C | 19.1mm(0.75”) |

| D | 26.7mm(1.05”) |

Ideal Applications: Where This Membrane Excels

This isn’t a one-size-fits-all component. It serves specific scenarios perfectly. For instance, it’s ideal for polishing already-treated water. Consider these uses:

- Final purification after ion exchange or softeners.

- Low-TDS groundwater or river water treatment.

- Boiler feed water preparation.

- Laboratory pure water systems.

- Food and beverage processing lines.

Conversely, it is not suited for high-TDS seawater or brackish water. Matching the membrane to your source water is crucial for efficiency.

Technical Specifications & Performance Data

Making an informed decision requires clear data. The BasideWT ULP 4040 RO Membrane comes with reliable and tested specifications.

- Model: BasideWT ULP-4040

- Dimensions: 4 inches in diameter, 40 inches in length.

- Max Operating Pressure: 150 psi.

- Max Feed Temperature: 113°F (45°C).

- pH Range: 4 – 11 (continuous operation).

- Average Permeate Flow: 2,400 GPD (under standard test conditions).

- Minimum Salt Rejection: 99.0%

Specifically, always ensure your pre-filtration (like 5-micron sediment filters) is optimal. This protects the delicate membrane surface.

how to change 4040 ro membrane?

Step 1: Remove the Pressure Vessel

- Disconnect the inlet, concentrate, and permeate tubing from the pressure vessel housing.

- Use the appropriate housing wrench to loosen and remove the end caps.

- For larger RO systems, note that the pressure vessels may be mounted on a rack—ensure the system is depressurized before removal.

Step 2: Extract the Old Membrane

- Carefully slide the old membrane element out of the housing.

- Tip: Observe the membrane’s flow direction before removal. The feed side typically has the brine seal (a thicker O-ring).

- Dispose of the old membrane according to local regulations.

Step 3: Clean the Pressure Vessel

- Rinse the interior of the housing and the end caps thoroughly with clean water.

- Inspect the brine seal groove and all interconnector O-rings.

- Clean them properly and replace any O-rings that appear worn, cracked, or damaged.

Step 4: Install the New Membrane

- Lubricate: Apply a suitable, RO-compatible lubricant to the new membrane’s brine seal and all O-rings.

- Insert Correctly: Slide the new membrane into the housing with the feed end (brine seal side) entering first toward the inlet.

- Push the membrane in gently but firmly until it is fully seated.

- Important: Ensure the membrane’s concentrate (reject) outlet is perfectly aligned with the housing’s outlet port to prevent leakage or performance loss.

Step 5: Reassemble the Housing

Verify all connections are secure before restarting the system.

Reinstall the end caps and tighten them evenly using the housing wrench. Avoid over-tightening to prevent damage.

Reconnect all tubing to their corresponding inlet, concentrate, and permeate ports.

Common Mistakes & How to Avoid Them

Many users unknowingly harm their 4040 RO Membrane. Here’s what to watch for:

❌ High Chlorine Exposure – Even 1 ppm can degrade the membrane over time. Ignoring pH Levels – Keep feed water between 5-8 pH for longevity.Infrequent Cleaning – Clean every 6 months (or when flux drops 15%).

Real-World Case Study: Beverage Plant Optimization

In 2025, our team upgraded a bottling facility’s RO system with ULP 4040 membranes. Results?

- 💧 20% higher flow rate

- 💰 $12k/year energy savings

- 🔄 Fewer membrane replacements

The key? Proper maintenance and regular monitoring.

RO Membrane Packaging

Water Treatment Accessories Selection Guide

Whole House Water Filtration System

UV Sterilizers

RO Membrane

Water Filter Housings

Water Filter Cartridge

Control Valves

Choose between manual, semi-automatic, or fully automatic valves depending on system complexity and maintenance needs.

Water Distributor for FRP Tanks

Brine Tanks

Ion Exchange Resins

Water Pressure Gauge

Water Purifier Quick Connector

Water Purifier Quick connector are small fittings. They join water lines in purification systems. You find them in residential RO units. They connect membranes to housings. They link filters to faucets. Their design is brilliant. They allow push-to-connect installation. No tools are needed. No twisting or tightening.

FAQs

Choosing the perfect water treatment system depends on your specific water quality, household size, and needs. We make it easy with our 3-step process:

Water quality testing – analyze your water for contaminants, hardness, and other factors.

Personalized Consultation – Our experts recommend systems based on your results, budget, and water usage.

Customized Solution – From whole-house filtration to targeted solutions (e.g., RO for drinking water, softeners for hard water), we tailor the system to your home.

To determine your water flow rate in gallons per minute (GPM), follow these simple steps:

Prepare for Testing:

- Prepare for Testing:

- Ensure all water fixtures in your home are turned off

- Select the faucet closest to your main water supply line (usually the kitchen sink or an outdoor spigot)

- Conduct the Test:

- Fully open the selected faucet

- Time how many seconds it takes to fill a 1-gallon container

- Repeat the test 2-3 times for accuracy

- Calculate Your Flow Rate:

Use this formula: Flow Rate (GPM) = 60 ÷ Fill Time (seconds)Example Calculation:- If your 1-gallon container fills in 15 seconds

- 60 ÷ 15 = 4 GPM

For more precise measurements or whole-home flow rate analysis, contact our water system specialists. We can help you determine if your current flow rate meets the requirements for any water treatment systems you’re considering.

1. Check Multiple Fixtures

Test water pressure at different faucets, showers, and appliances (e.g., kitchen sink, bathroom sink, outdoor hose).

If only one fixture has low pressure, the problem is likely localized (clogged aerator, faulty valve, or pipe issue).

If all fixtures have low pressure, the issue is systemic (main supply, pressure regulator, or water heater).

2. Inspect the Aerator or Showerhead

Unscrew the faucet aerator or showerhead and check for mineral deposits, debris, or rust.

Soak it in vinegar overnight to dissolve buildup, then rinse and reattach.

3. Check the Main Shutoff Valve

Locate the main water shutoff valve (usually near the water meter or where the main line enters the house).

Ensure it’s fully open (turn clockwise to close, counterclockwise to open).

1. Activated Carbon Filters

- Removes:

✅ Chlorine & chloramines

✅ Bad tastes & odors (e.g., sulfur)

✅ Volatile Organic Compounds (VOCs)

✅ Some pesticides & herbicides

❌ Does not remove heavy metals, dissolved minerals, or microbes

2. Reverse Osmosis (RO) Systems

- Removes:

✅ Heavy metals (lead, arsenic, mercury, cadmium)

✅ Dissolved salts (fluoride, nitrates, sulfates)

✅ Microplastics & sediment

✅ Bacteria & viruses (if combined with UV)

✅ Chlorine & chemicals (with carbon pre-filter)

❌ May remove beneficial minerals (can be remineralized)

3. Water Softeners (Ion Exchange)

- Targets:

✅ Calcium & magnesium (hardness)

✅ Low levels of iron & manganese

❌ Does not remove bacteria, chlorine, or heavy metals

4. UV Purifiers

- Kills:

✅ Bacteria (E. coli, coliform)

✅ Viruses (rotavirus, hepatitis)

✅ Protozoa (Giardia, Cryptosporidium)

❌ Does not remove chemicals, metals, or sediment

5. Sediment Filters

- Removes:

✅ Sand, rust, dirt

✅ Large particles & silt

❌ Does not remove dissolved contaminants

6. Whole-House Filtration Systems

Combines multiple methods (carbon + sediment + UV) for broad protection.

- UV: Kills bacteria/viruses but doesn’t remove chemicals or particles.

- RO (Reverse Osmosis): Removes 95–99% of contaminants (heavy metals, dissolved salts) but requires electricity.

- Activated Carbon: Absorbs chlorine, odors, and organic compounds—ideal for pre-filtration.

REQUEST A QUOTE

RELATED PRODUCTS

Cheap Price UPL4021 4040 8040 RO Membrane for Water Treatment Reverse Osmosis System

High Quality Double O Ring 1812/3012/3013/3213 Plastic RO Membrane Housing Shell for Residential RO Water Filter Use

Water ULP Ultra Low Pressure Industrial 8040 Reverse Osmosis Membrane Element 8″ x 40″

Household Hollow Fiber UF Water Filter Cartridge 1/4″ NPT

Reverse Osmosis Membrane 3013-400G 600G ro membrane change For Home RO Drinking Water Purifier System