BasideWT- Whole Home Water Filtration System & Replacement

Reverse Osmosis Membrane | BasideWT

Introduction

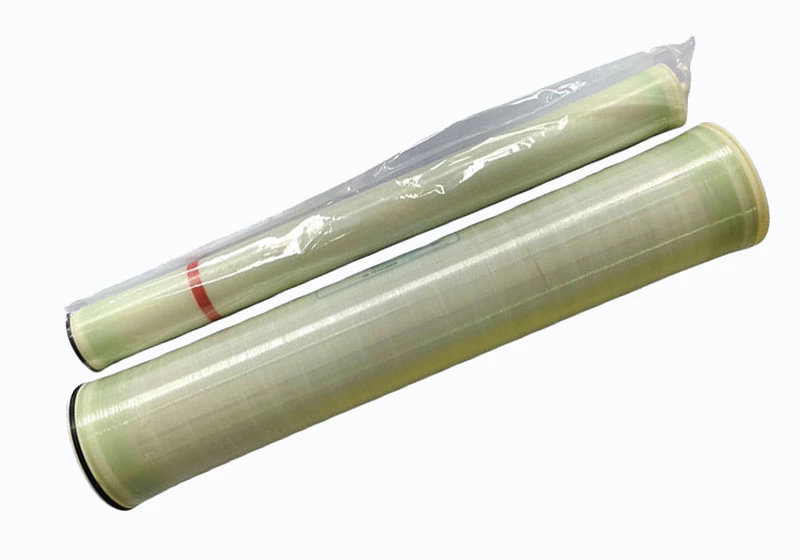

Reverse Osmosis (RO) membrane technology has become a cornerstone in modern water purification and desalination systems. Whether in large-scale industrial water treatment plants or high-end residential purification units, the Reverse Osmosis Membrane plays a crucial role in achieving ultra-pure water quality.

BasideWT, a global leader in membrane and filtration technologies, provides high-performance RO membranes engineered for superior efficiency, durability, and cost-effectiveness.

What Is a Reverse Osmosis Membrane?

A Reverse Osmosis Membrane is a semi-permeable barrier that allows water molecules to pass while rejecting salts, organics, and impurities. It functions as the heart of any RO system, separating feed water into permeate (purified water) and concentrate (reject stream) through the application of pressure higher than the natural osmotic pressure.

RO membranes are widely used in industrial applications, seawater desalination, power plants, and residential water purification systems. By using a physical separation process, they eliminate the need for chemical disinfectants and deliver consistent water purity with low operational costs.

Working Principle of Reverse Osmosis

The working mechanism of an RO membrane relies on osmotic pressure reversal. In nature, water flows from a low-salinity area to a high-salinity area through a semi-permeable membrane (osmosis). In reverse osmosis, external pressure is applied to push water from the high-salinity side to the low-salinity side, forcing pure water molecules through the membrane while rejecting dissolved solids.

Key Stages of RO Filtration

- Pre-Filtration: Removes sediments, chlorine, and organics that could damage the membrane.

- Pressurization: Feed water is pressurized using a high-pressure pump.

- Membrane Separation: Water molecules pass through the RO membrane; contaminants are retained and flushed away.

- Post-Treatment: pH adjustment or remineralization to meet specific water quality requirements.

Membrane Material and Structure

Modern Reverse Osmosis Membranes are typically made from thin-film composite (TFC) materials — primarily polyamide. The structure consists of three layers:

- Polyamide (PA) active layer: Responsible for selective salt rejection.

- Polysulfone (PSF) support layer: Provides mechanical strength.

- Nonwoven polyester base: Acts as structural support.

This multi-layer configuration ensures a balance between high water permeability and excellent salt rejection efficiency, typically exceeding 98–99.5%.

Applications of Reverse Osmosis Membranes

1. Industrial Water Treatment

RO membranes are extensively used in power plants, refineries, food and beverage industries, and semiconductor manufacturing. BasideWT membranes ensure high-purity water for steam generation, process use, and product formulation.

2. Seawater Desalination

Seawater RO (SWRO) membranes convert saline water into potable water. BasideWT provides energy-efficient membranes capable of operating at high pressures (up to 80 bar), delivering reliable desalination for coastal and island communities.

3. Residential and Commercial Purification

RO systems in homes and offices use smaller spiral-wound membranes to remove hardness, chlorine, heavy metals, and bacteria—ensuring safe, great-tasting drinking water.

4. Wastewater Reclamation

RO membranes also enable the recycling of industrial and municipal wastewater, reducing discharge and promoting sustainability through water reuse.

Pretreatment and Maintenance

The performance and longevity of RO membranes depend heavily on feed water pretreatment. BasideWT recommends the following measures:

- Sediment filtration to remove suspended solids.

- Activated carbon filtration for chlorine and organics.

- Antiscalant dosing to prevent scale formation.

- Periodic membrane cleaning using low-pH and high-pH cleaners.

Proper maintenance can extend the membrane lifespan to 3–5 years, reducing downtime and operating costs.

Advantages of BasideWT Reverse Osmosis Membranes

- High Salt Rejection: >99.5% for dissolved solids and contaminants.

- Energy Efficiency: Optimized flow channels reduce pressure loss.

- Durable Construction: Resistant to fouling, compaction, and temperature variations.

- Versatile Applications: Suitable for seawater, brackish water, and tap water treatment.

- Global Support: Technical assistance and performance monitoring for industrial clients.

ULP / Low Pressure RO Membrane

Using advanced thin-film composite (TFC) technology, BasideWT ULP membranes achieve high salt rejection rates.

High Salt Rejection: Removes up to 99% of dissolved salts, heavy metals, and organic contaminants.

Energy Efficient: Reduces power consumption and operational costs in large-scale systems.

Wide Application Range: Suitable for tap water, brackish water, and pre-treatment for industrial RO systems.

Durable TFC Design: Resistant to chemical degradation and fouling for long service life.

Anti-Fouling RO Membrane

High Salt Rejection: Maintains excellent desalination efficiency (>99%) under demanding conditions.

Stable Performance: Sustains high permeate flux even with challenging feed water quality.

Extended Cleaning Interval: Reduces the frequency of chemical cleaning and maintenance.

Long Service Life: Improved resistance to biofouling, scaling, and chemical degradation.

Energy Efficient: Lower fouling leads to stable pressure and reduced energy consumption.

Seawater RO Membrane

Optimized for High Pressure: Designed to operate effectively at pressures up to 8.3 MPa (1200 psi).

Energy-Saving Design: Advanced polyamide layer enables high permeate flow at lower specific energy consumption.

Anti-Fouling & Anti-Scaling: Surface modification minimizes scaling, organic fouling, and biofilm growth.

Durable & Long-Lasting: Resistant to chemical and mechanical stress for long service life in harsh marine environments.

Wide Compatibility: Suitable for both single-pass and two-pass desalination systems.

Household RO Membrane

Superior Filtration Quality: Effectively eliminates heavy metals, bacteria, and organic impurities.

Stable Performance: Maintains consistent permeate flow under variable feed conditions.

Long Service Life: High-quality TFC material resists fouling and chemical degradation.

Universal Fit Design: Compatible with most standard 50GPD–100GPD domestic RO systems.

Energy Efficient: Delivers high output at low operating pressure, saving water and power.

Is It Time to Change Your RO Membrane? Here’s How to Tell.

Think of your Reverse Osmosis (RO) system as the guardian of your home’s drinking water. And at the very core of this guardian is the RO membrane—the unsung hero that tirelessly filters out contaminants, turning ordinary tap water into clean, refreshing water you can trust. Because it works so hard, knowing when to retire this vital component is key to maintaining your water’s purity and your system’s health.

While you might hear a standard rule of thumb—replace it every 3 to 5 years—this isn’t a one-size-fits-all answer. The true lifespan of your membrane depends on the quality of water it processes and how much you use your system. If it’s still performing well after five years, it might not be ready for retirement just yet.

So, how can you tell if your membrane is losing its strength? Your RO system will usually send you a few clear signals.

The Telltale Signs of a Worn-Out RO Membrane

- The Slowdown: This is the most common red flag. You’ll notice that the stream of water from your RO faucet has become more of a tired trickle. Filling a glass or a pot takes noticeably longer than it used to. This means the membrane is becoming clogged and can’t let water pass through as easily.

- The Non-Stop Runner: Does it seem like your RO system is almost always running? A properly functioning system should fill its storage tank and then shut off. If it seems to be humming away constantly, it’s a sign the membrane is struggling to produce enough purified water to pressurize the tank, forcing the system to work overtime.

- A Change in Water Quality: Trust your senses. Does the water taste or smell “off”? While not always conclusive, a noticeable shift in taste or an increase in spotting on your glasses after dishwashing can be an early indicator that the membrane is no longer effectively filtering out dissolved solids.

The Real Test: Measuring Water Quality with a TDS Meter

While the signs above are helpful clues, the most accurate way to check your membrane’s health is with a simple, inexpensive tool: a TDS (Total Dissolved Solids) meter. TDS measures the total amount of minerals, salts, and metals dissolved in your water, expressed in parts per million (ppm).

- Typical Tap Water: Can range from 300 to over 500 ppm.

- Well Water: Can vary dramatically, from very low to extremely high ppm levels.

The goal of your RO system isn’t to achieve a specific TDS number, but to reduce the incoming TDS by a significant percentage, known as its rejection rate. A new, healthy membrane typically has a rejection rate of 90% to 97%.

How to Perform a Simple Health Check on Your Reverse Osmosis Membrane

Grab your TDS meter and follow these steps:

- Test Your Feed Water: Draw a sample from your regular kitchen cold water tap (this is the water entering your RO system). Record the reading. Let’s call this number A.

- Test Your RO Water: Now, draw a sample from your dedicated RO faucet. Make sure the system has been running for a moment to get a fresh sample. Record this reading. Let’s call this number B.

- Calculate the Rejection Rate: Plug your numbers into this simple formula:Rejection Rate % = (A – B) / A x 100

- Example: If your tap water (A) is 300 ppm and your RO water (B) is 15 ppm, your calculation would be: (300 – 15) / 300 x 100 = 95%. This indicates a perfectly healthy membrane!

What Really Determines How Long Your RO Membrane Lasts?

While the 3-5 year guideline is a helpful starting point, the actual lifespan of your RO Reverse Osmosis membrane is deeply personal—it depends entirely on the unique conditions in your home. Think of the membrane not as having a fixed expiration date, but as a hardworking component whose retirement age is decided by a few key factors.

Here’s a closer look at what can shorten or extend its service life.

1. The Quality of Your Incoming Water

This is the number one factor. Your membrane’s longevity is a direct response to the “diet” of water you feed it.

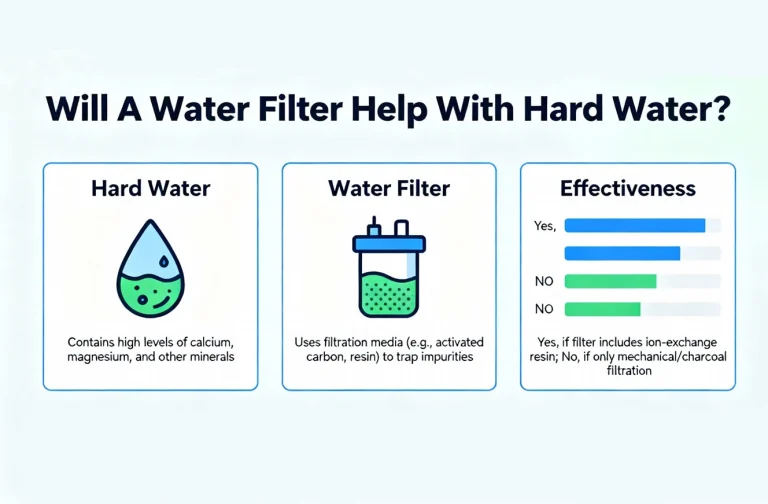

- High Mineral Content (Hard Water): Water rich in calcium and magnesium is a primary culprit for scaling. These minerals can crystallize and clog the membrane’s microscopic pores, much like arteries getting clogged with cholesterol, forcing it to work harder and fail faster.

- Chlorine & Chloramines: While used to disinfect municipal water, chlorine is a kryptonite to the thin-film composite material of most RO membranes. Consistent exposure can cause the membrane to physically degrade, compromising its ability to filter effectively.

- Sediment & Organic Matter: High levels of silt, rust, or other suspended particles can physically foul the membrane surface, blocking the path for water to pass through.

2. The First Line of Defense: Your Pre-Filters

The RO membrane is the star quarterback, and the pre-filters are the offensive line. Their job is to take the hits so the quarterback doesn’t have to

- A sediment filter protects the membrane from physical fouling by trapping dirt and rust.

- A carbon filter is crucial for neutralizing chlorine and other chemicals before they can damage the sensitive membrane.

Neglecting to change these pre-filters on time is like asking your quarterback to play without a line—the membrane will bear the full brunt of contaminants, leading to a premature end.

3. Your Household’s Water Consumption

It’s simple math: the more water you use, the more work the membrane does. A large family that cooks, drinks, and uses RO water for coffee will naturally exhaust their membrane faster than a single person in the same home. It’s about the total volume of water filtered, not just the passage of time.

4. The Often-Forgotten Factor: System Maintenance

An RO system isn’t a “set it and forget it” appliance. Regular maintenance is non-negotiable.

- Timely Pre-Filter Changes: As mentioned, this protects the membrane. A clogged sediment filter strains the entire system.

- Professional Check-ups: Having a technician occasionally check the system’s pressure and flow can identify issues before they cause irreversible damage to the membrane.

5. Operating Pressure and Temperature

RO membranes are engineered to perform within specific pressure and temperature ranges.

- Low Water Pressure: If your home’s water pressure is consistently too low, the membrane will struggle to push water through its pores, leading to poor production and increased contaminant concentration on one side, which can cause fouling.

- Extreme Temperatures: Very cold water is harder to push through the membrane, while very hot water can damage its polymer structure.

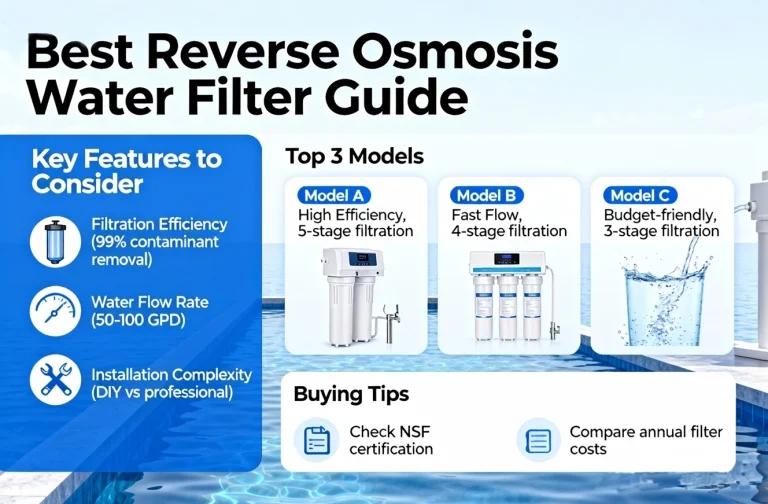

Water Treatment Accessories Selection Guide

Let’s Solve Your Water ChallengesOur BasideWT water specialists are ready to assist.

-

WhatsAPP: 86-13548779363

-

Mobile: 86-135 4877 9363

-

Email: sales@basidewt.com

-

Business hours: Aibang Technology Industrial Park, No. 559 Yun Qi Lu,Yuelu District, Changsha, Hunan, China

-

Address: Aibang Technology Industrial Park, No. 559 Yun Qi Lu,Yuelu District, Changsha, Hunan, China