BasideWT- Whole Home Water Filtration System & Replacement

What Is Water Treatment Plant?

Have you ever paused while filling a glass from your tap to consider the journey that water took to reach you? That clean, safe water is made possible by a critical infrastructure system that most of us never see. So, what is water treatment plant? In simple terms, it is a specialized facility designed to remove contaminants and harmful substances from raw water sources—like rivers, lakes, and groundwater—making it safe for human consumption and use. These plants are engineering marvels that combine physical, chemical, and biological processes to protect public health and the environment. At BasideWT, we believe that understanding the “what” and “how” of these facilities is the first step toward appreciating the value of every drop.

The Critical Need: Why We Can’t Just Drink from the River

Imagine taking a drink directly from a local river. It seems natural, but it’s incredibly risky. Why? Because raw water is a complex cocktail of invisible threats.

It can contain:

- Sediment and Turbidity: Silt, sand, and clay that make water cloudy.

- Pathogenic Microorganisms: Bacteria, viruses, and parasites that cause diseases like cholera and dysentery.

- Dissolved Chemicals: Natural compounds like excessive minerals and human-made pollutants like pesticides and industrial waste.

- Organic Matter: Decaying leaves and plants, which can react with disinfectants to form harmful by-products.

Therefore, the primary mission of any water treatment plant is to serve as a barrier between these potential hazards and our communities. It is a non-negotiable component of modern public health infrastructure. Without it, waterborne diseases would be rampant, and our quality of life would be drastically different.

The Journey of a Water Drop: Inside the Multi-Stage Treatment Process

The transformation of raw water into potable water is not a single event but a meticulous, multi-step journey. Each stage is designed to target specific types of contaminants, building upon the previous one to achieve a cumulative effect of purity.

Initial Screening and Coagulation/Flocculation

The journey begins with screening. Water enters the plant and passes through large bars screens. These screens remove the biggest debris. Think of sticks, leaves, plastic, and even fish. This is a simple but vital first step to protect the more delicate equipment downstream.

Next comes a chemical dance known as coagulation and flocculation. Here, a chemical coagulant—typically a salt like aluminum sulfate or ferric chloride—is added to the water. This coagulant has a positive electrical charge.

Why does this matter? Most dissolved particles and dirt in the water carry a negative charge. This causes them to repel each other, staying suspended forever. The positively charged coagulant neutralizes the negative charges. Suddenly, the fine particles can stick together, forming larger, fluffy clumps called “floc.” This process is like using a magnet to gather scattered iron filings.

Sedimentation and Filtration: The Great Separation

Now that we have floc, it’s time for it to go. The water flows gently into a settlement tank, or clarifier, in a step called sedimentation. The water velocity slows down dramatically, allowing the heavy, newly formed floc to settle to the bottom under its own weight due to gravity. After several hours, the water at the top of the tank is significantly clearer. The settled floc, now called “sludge,” is removed for separate processing.

But the water isn’t clean yet. It still holds microscopic particles. This is where filtration acts as the final polishing step. The water is passed through layers of filtering media. A common filter bed might consist of anthracite coal, sand, and gravel. These layers work together to trap any remaining floc, tiny particles, and some microorganisms. The result is water that is visually crystal clear.

The Final Guard: Disinfection

Clear water is not necessarily safe water. The most dangerous contaminants—pathogenic bacteria and viruses—are too small to be caught by filtration. Therefore, the final and arguably most crucial step is disinfection.

Plants use different methods to achieve this:

- Chlorination: Adding chlorine is the most common method. It is highly effective at killing pathogens and provides a “residual” that protects the water as it travels through miles of pipes to your home.

- UV Disinfection: Exposing water to ultraviolet light is a chemical-free process that damages the DNA of microorganisms, rendering them harmless.

- Ozonation: Injecting ozone gas is a powerful oxidant that kills microbes and can improve taste and odor.

Interestingly, while chlorination is a powerhouse for safety, it can react with natural organic matter to form disinfection byproducts (DBPs). Modern plants must carefully balance effective disinfection with the minimization of these DBPs.

Beyond the Basics: Advanced and Specialized Treatments

The conventional process handles most situations. But what about more stubborn pollutants? This is where advanced treatments come into play.

Counterintuitively, the very disinfectant that keeps us safe (chlorine) can sometimes be the source of taste and odor issues. To address this and other complex challenges, plants may employ:

- Activated Carbon Filtration: This is highly effective at removing organic compounds, pesticides, and chlorine, significantly improving taste and smell.

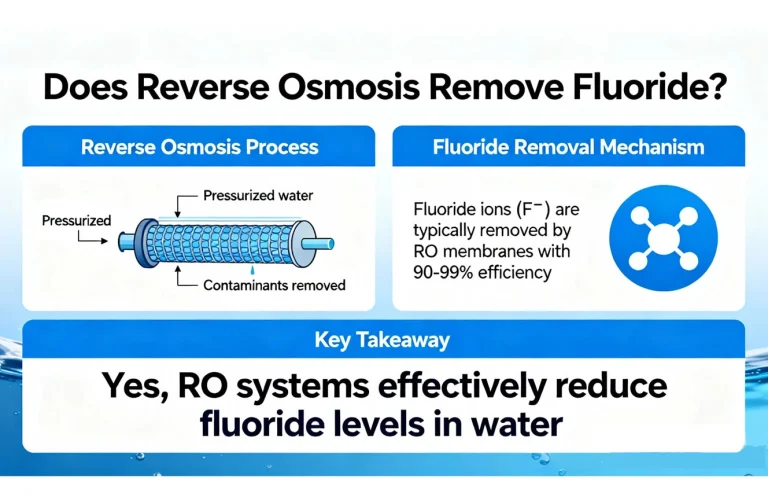

- Reverse Osmosis (RO): This forces water through a semi-permeable membrane, removing virtually all dissolved salts, ions, and other contaminants. It’s often used in desalination and for treating water with high nitrate or heavy metal content.

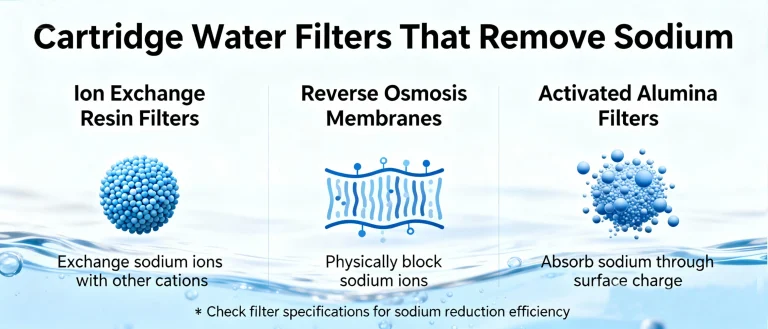

- Ion Exchange: Best known for water softening, this process swaps undesirable ions (like calcium and magnesium) for more desirable ones (like sodium or hydrogen).

At BasideWT, we specialize in integrating these advanced technologies into compact, efficient systems for both municipal and industrial applications, ensuring water quality meets the highest standards.

Different Types of Plants: Meeting Diverse Needs

It’s also important to recognize that not all facilities are the same. The core question, “what is water treatment plant?”, actually has multiple answers depending on the water’s source and intended use.

- Municipal Water Treatment Plants: These are the large-scale facilities we’ve primarily discussed, serving cities and towns.

- Wastewater Treatment Plants: Their role is different. They treat water that has already been used in homes and businesses (sewage) to a level safe enough to be released back into the environment.

- Desalination Plants: These are specialized facilities, often using reverse osmosis, to remove salt from seawater, making it potable.

- Package Plants: These are compact, pre-assembled units used for small communities or specific industrial purposes.

Facing Modern Challenges: The Future of Water Treatment

The work of water treatment is never finished. Plants today face unprecedented challenges, from aging infrastructure to emerging contaminants.

However, it’s worth noting that new threats are constantly being identified. These include:

- Microplastics: Tiny plastic particles pervasive in the environment.

- Pharmaceuticals and Personal Care Products (PPCPs): Trace amounts of medicines, hormones, and cosmetics that pass through our bodies and into the water cycle.

- PFOA/PFOS: Persistent “forever chemicals” used in many industrial and consumer products.

Tackling these requires continuous research, innovation, and investment in next-generation treatment technologies. The future of water treatment lies in smarter, more adaptive, and more energy-efficient processes.