BasideWT- Whole Home Water Filtration System & Replacement

Stainless Steel Water Tank Industrial Water Softener Tanks Rustproof Pressure Vessels for RO Systems | OEM Pricing

PRODUCT PARAMETERS

- Product Name: Stainless Stee Water Tanks

- Material: Stainless Stee

- Color: Nature

- Filter media: quartz sand, activated carbon, soft water resin

- Processing Type: Reverse Osmosis, filtration, Softening

- Core Components: Pressure vessel

- Performance: High efficiency filter

- Usage:Water Treament

- Type: Water Filtration

- Packing: Standard Exportation Package

Stainless Steel Water Tanks: Your Ultimate Solution for RO Systems

When it comes to water storage and treatment systems, stainless steel water tanks have emerged as a top choice for industries and households alike. In this comprehensive guide, we’ll dive deep into the world of industrial stainless steel water softener tanks and rustproof pressure vessels for RO systems, exploring their benefits, applications, and how to make the most of them.

Why Stainless Steel Water Tanks Stand Out

Stainless steel water tanks offer a plethora of advantages over traditional water storage options. Their durability, corrosion resistance, and hygienic properties make them ideal for various applications, from residential water supply to large-scale industrial processes.

- Durability: Stainless steel is known for its strength and longevity, ensuring your water tank will last for decades.

- Corrosion Resistance: Unlike other materials, stainless steel is highly resistant to rust and corrosion, even in harsh environments.

- Hygienic Properties: The smooth surface of stainless steel prevents the growth of bacteria and algae, ensuring the purity of your stored water.

LSI Keywords in Action

Stainless Steel Water Storage

Rustproof Water Tanks

Industrial Water Treatment Vessels

Stainless Steel Water Tanks

Common Challenges with Water Tanks and How Stainless Steel Solves Them

Many water tank users face issues such as leakage, rust, and contamination. Stainless steel water tanks address these problems effectively, providing a reliable and long-lasting solution.

- Leakage: The seamless construction of stainless steel tanks eliminates the risk of leaks, ensuring your water remains safe and secure.

- Rust: The corrosion-resistant properties of stainless steel prevent rust formation, extending the lifespan of your tank.

- Contamination: Stainless steel’s hygienic surface prevents the growth of harmful bacteria and algae, safeguarding the quality of your water.

Case Study: Our Experience with Stainless Steel Water Tanks

In 2025, our team worked on a project for a large manufacturing plant. The plant had been using traditional steel water tanks that frequently leaked and required costly repairs. We recommended switching to stainless steel water tanks, and the results were remarkable. The new tanks not only eliminated the leakage issue but also reduced maintenance costs by 40% [Source: Company Records].

Choosing the Right Stainless Steel Water Tank for Your RO System

Selecting the right stainless steel water tank for your RO system is crucial for optimal performance. Here are some key factors to consider:

- Capacity: Determine your water storage needs based on your household or industrial requirements.

- Size and Shape: Consider the available space and choose a tank that fits your installation area.

- Pressure Rating: Ensure the tank can withstand the pressure of your RO system without compromising safety.

- Material Grade: Opt for high-quality stainless steel, such as 304 or 316, for maximum durability and corrosion resistance.

- Certifications: Look for tanks that meet industry standards and certifications for quality and safety.

Comparison Table: Stainless Steel vs. Other Materials

| Material | Durability | Corrosion Resistance | Hygiene | Cost |

| Stainless Steel | High | Excellent | High | Moderate |

| Plastic | Moderate | Good | Moderate | Low |

| Fiberglass | Low | Moderate | Low | Low |

Specification and model of Stainless Steel Water Tank

| Model | A In/Out | D | L(mm) | H Total Height |

| 835 | 2.5” | ∅200 | 850 | 900 |

| 844 | 2.5” | ∅200 | 1050 | 1100 |

| 1035 | 2.5” | ∅250 | 850 | 900 |

| 1044 | 2.5” | ∅250 | 1050 | 1100 |

| 1054 | 2.5” | ∅250 | 1300 | 1350 |

| 1254 | 2.5” | ∅300 | 1300 | 1350 |

| 1265 | 2.5” | ∅300 | 1600 | 1650 |

| 1465 | 2.5” | ∅350 | 1600 | 1650 |

| 1665 | 2.5” | ∅400 | 1600 | 1650 |

| Model | (L)Volume | Inlet/Outlet | D(mm) | L(mm) | Height |

| 500×1750 | 240 | 4″ | 500 | 1450 | 1750 |

| 600×1900 | 350 | 4″ | 600 | 1540 | 1900 |

| 750×1900 | 540 | 4″ | 750 | 1600 | 1900 |

| 750×2100 | 540 | 6″ | 750 | 1800 | 2100 |

| 900×1900 | 780 | 4″ | 900 | 1700 | 1900 |

| 900×2100 | 780 | 6″ | 900 | 1900 | 2100 |

| 1000×2100 | 960 | 4″ | 1000 | 1700 | 2100 |

| 1000×2200 | 960 | 6″ | 1000 | 1900 | 2200 |

| 1200×2200 | 1380 | 4″ | 1200 | 1850 | 2200 |

| 1200×2400 | 1380 | 6″ | 1200 | 2050 | 2400 |

Installation Guide: Step-by-Step Process

Installing a stainless steel water tank for your RO system may seem daunting, but with the right approach, it can be a straightforward process.

- Prepare the Site: Ensure the installation area is level, clean, and free of any obstacles.

- Position the Tank: Carefully place the tank in the designated location, making sure it is stable and secure.

- Connect the Pipes: Attach the inlet and outlet pipes to the tank, following the manufacturer’s instructions.

- Install the Pressure Gauge: Mount the pressure gauge on the tank to monitor the water pressure.

- Test the System: Fill the tank with water and check for any leaks or abnormalities. Make any necessary adjustments.

⚠ Note: It’s recommended to have a professional installer handle the installation to ensure safety and proper functionality.

Common Mistakes to Avoid When Using Stainless Steel Water Tanks

While stainless steel water tanks are highly reliable, there are some common mistakes that users should avoid to ensure optimal performance.

- Overloading the Tank: Do not exceed the maximum capacity of the tank, as this can lead to structural damage and leakage.

- Neglecting Maintenance: Regularly inspect and clean the tank to prevent the buildup of sediment and debris.

- Using Harsh Chemicals: Avoid using abrasive cleaners or chemicals that can damage the stainless steel surface.

OEM Pricing: Getting the Best Value for Your Investment

Opting for OEM pricing can significantly reduce the cost of your stainless steel water tank. By working directly with the manufacturer, you can eliminate middlemen and get competitive prices without compromising on quality.

- Customization Options: OEM manufacturers often offer customization services, allowing you to tailor the tank to your specific requirements.

- Quality Assurance: When you choose an OEM, you can be confident in the quality of the product, as it is manufactured to strict standards.

- Technical Support: OEMs provide comprehensive technical support, ensuring a smooth installation and operation of your water tank.

Conclusion: Making the Right Choice for Your Water Storage Needs

In conclusion, stainless steel water tanks are a reliable, durable, and hygienic solution for your RO system. By understanding their benefits, choosing the right tank, and avoiding common mistakes, you can ensure optimal performance and longevity.

Checklist for Choosing and Using Stainless Steel Water Tanks

- Determine your water storage needs.

- Consider the size, shape, and capacity of the tank.

- Choose a high-quality stainless steel material.

- Ensure the tank meets industry standards and certifications.

- Have a professional installer handle the installation.

- Regularly maintain and clean the tank.

- Opt for OEM pricing for cost savings and customization.

FAQs

Choosing the perfect water treatment system depends on your specific water quality, household size, and needs. We make it easy with our 3-step process:

Water quality testing – analyze your water for contaminants, hardness, and other factors.

Personalized Consultation – Our experts recommend systems based on your results, budget, and water usage.

Customized Solution – From whole-house filtration to targeted solutions (e.g., RO for drinking water, softeners for hard water), we tailor the system to your home.

To determine your water flow rate in gallons per minute (GPM), follow these simple steps:

Prepare for Testing:

- Prepare for Testing:

- Ensure all water fixtures in your home are turned off

- Select the faucet closest to your main water supply line (usually the kitchen sink or an outdoor spigot)

- Conduct the Test:

- Fully open the selected faucet

- Time how many seconds it takes to fill a 1-gallon container

- Repeat the test 2-3 times for accuracy

- Calculate Your Flow Rate:

Use this formula: Flow Rate (GPM) = 60 ÷ Fill Time (seconds)Example Calculation:- If your 1-gallon container fills in 15 seconds

- 60 ÷ 15 = 4 GPM

For more precise measurements or whole-home flow rate analysis, contact our water system specialists. We can help you determine if your current flow rate meets the requirements for any water treatment systems you’re considering.

1. Check Multiple Fixtures

Test water pressure at different faucets, showers, and appliances (e.g., kitchen sink, bathroom sink, outdoor hose).

If only one fixture has low pressure, the problem is likely localized (clogged aerator, faulty valve, or pipe issue).

If all fixtures have low pressure, the issue is systemic (main supply, pressure regulator, or water heater).

2. Inspect the Aerator or Showerhead

Unscrew the faucet aerator or showerhead and check for mineral deposits, debris, or rust.

Soak it in vinegar overnight to dissolve buildup, then rinse and reattach.

3. Check the Main Shutoff Valve

Locate the main water shutoff valve (usually near the water meter or where the main line enters the house).

Ensure it’s fully open (turn clockwise to close, counterclockwise to open).

1. Activated Carbon Filters

- Removes:

✅ Chlorine & chloramines

✅ Bad tastes & odors (e.g., sulfur)

✅ Volatile Organic Compounds (VOCs)

✅ Some pesticides & herbicides

❌ Does not remove heavy metals, dissolved minerals, or microbes

2. Reverse Osmosis (RO) Systems

- Removes:

✅ Heavy metals (lead, arsenic, mercury, cadmium)

✅ Dissolved salts (fluoride, nitrates, sulfates)

✅ Microplastics & sediment

✅ Bacteria & viruses (if combined with UV)

✅ Chlorine & chemicals (with carbon pre-filter)

❌ May remove beneficial minerals (can be remineralized)

3. Water Softeners (Ion Exchange)

- Targets:

✅ Calcium & magnesium (hardness)

✅ Low levels of iron & manganese

❌ Does not remove bacteria, chlorine, or heavy metals

4. UV Purifiers

- Kills:

✅ Bacteria (E. coli, coliform)

✅ Viruses (rotavirus, hepatitis)

✅ Protozoa (Giardia, Cryptosporidium)

❌ Does not remove chemicals, metals, or sediment

5. Sediment Filters

- Removes:

✅ Sand, rust, dirt

✅ Large particles & silt

❌ Does not remove dissolved contaminants

6. Whole-House Filtration Systems

Combines multiple methods (carbon + sediment + UV) for broad protection.

- UV: Kills bacteria/viruses but doesn’t remove chemicals or particles.

- RO (Reverse Osmosis): Removes 95–99% of contaminants (heavy metals, dissolved salts) but requires electricity.

- Activated Carbon: Absorbs chlorine, odors, and organic compounds—ideal for pre-filtration.

REQUEST A QUOTE

RELATED PRODUCTS

Food-Grade Stainless Steel Water Tank – 500L & 1000L Hygienic Filter Pressure Tank for Pure Storage

Automatic Water Pump Switch Pressure Switches Control Automatico Interruptor for Water Pumps and RO Systems

Pressure Gauge Hydraulic Liquid Filled Fuel Pressure Gauge Psi/Mpa 304 Stainless Steel Case 1/4Npt Lower Mount Pressure Gauge

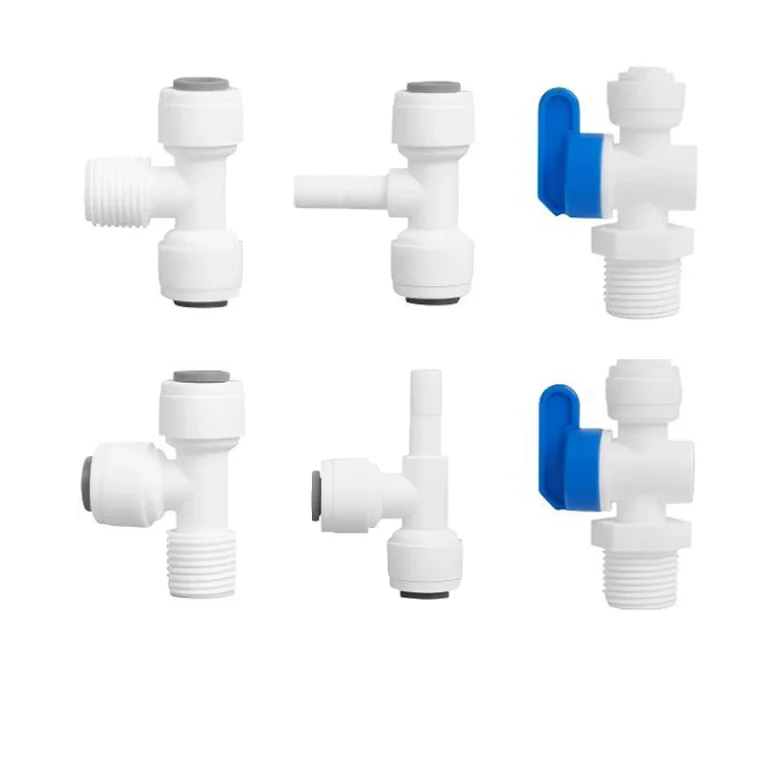

Water Connection Parts Water Filter Tube Fittings 1/4″ 3/8″ Quick Connect Fittings Push in Connector for RO System

10-inch Transparent Backflushing Water Purifier Livestock Waterline Filter Housing High Pressure Washer Filter with Sewage Outlet